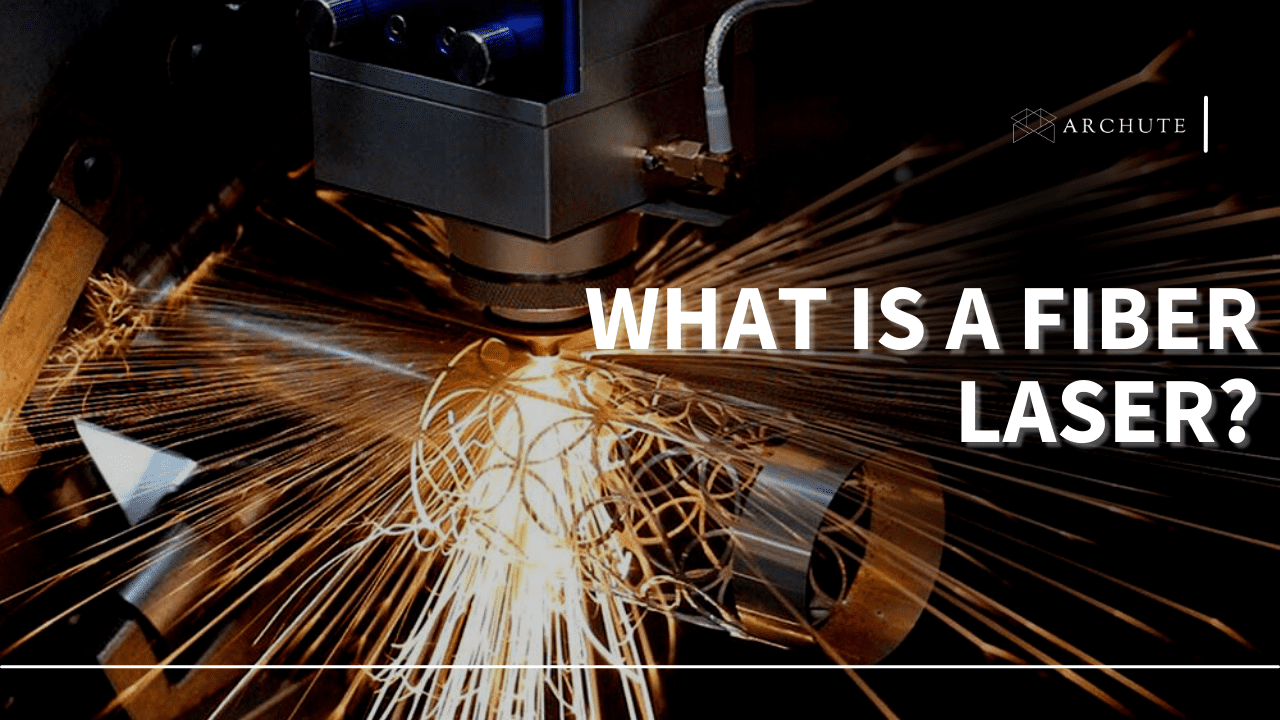

Fiber lasers are widely used today since they use optical fibers on active laser mediums to cut materials. These active laser mediums are a collection of atoms or molecules that exists in any state of matter; solid, liquid, gas, or plasma. They are used to determine the possible wavelengths emitted by the fiber lasers.

You can determine the wavelength of a material by monitoring specific transitions between the laser energy levels in the material. Fiber lasers make bulk production easier as they enable quick cutting and processing. So, if your question is, “what is a fiber laser?” Then, you can go through this article as we explain this laser-cutting tool and how it works.

What Is a Fiber Laser?

Image Credits: mac-tech.com

A fiber laser is a type of laser whereby the active gain medium uses an optical fiber doped with elements such as erbium, ytterbium, dysprosium, thulium, holmium, and dysprosium. These elements are related to doped fiber amplifiers that are responsible for light amplifications.

Doping is the process of adding impurities into a semiconductor to modulate its electrical, optical, and structural properties.

Fiber lasers use fiber optic cables made of silica glass to direct light. They produce a precise laser beam that is different from other lasers since they are straighter and smaller. They are also low maintenance, offer a small footprint, have good electrical efficiency, and have low operating costs.

How to Categorize Fiber Lasers

You can categorize fiber lasers using the following criteria:

1. Laser Source

You can differentiate a fiber laser by the element from which it was doped with. Some examples include ytterbium-doped fiber lasers, erbium-doped lasers, and thulium-doped fiber lasers. These lasers are used in different applications since they produce specific wavelengths.

2. Laser Power

You can categorize fiber lasers in terms of the laser power they emit; laser power represents the average power of a laser beam, expressed in watts. For instance, laser power can range from 20W to 50W, and so on. High-power fiber lasers generate more energy than low-power lasers.

3. Mode of Operation

Different types of fiber lasers release laser light differently. For example, you can get pulsed fiber lasers which work at a set repetition rate to release high laser light.

Alternatively, they can be progressive, meaning they continuously send the same amount of energy, thus referred to as continuous wave fiber lasers. You can get an extensive explanation of how laser cutters work here.

4. Mode

Mode is the size of the core where the light travels in the optical fiber. Fiber laser systems can be single-mode and multi-mode. The core diameter for single-mode lasers is small and can be between 8 and 9 micrometers, whereas large multi-mode lasers can be between 50 and 100 micrometers.

Single-mode lasers have better light amplification and beam quality than multi-mode fiber lasers.

What Are the Benefits of Using Fiber Lasers?

Before purchasing a fiber laser, you must consider some factors you will not find in other lasers. These factors distinguish fiber lasers, making them more special than other laser technologies. Most lasers have three components; a pumping source, the gain medium, and the optical resonator.

However, in fiber lasers, the pumping sources are between the laser diodes and other fiber lasers. They have very different gain medium and optical resonator designs. Their unique features are what makes them advantageous and function to give you the following benefits;

1. They Have a High-Output Power

Fiber lasers’ gain mediums are very thin and flexible, so their optical fibers are long, enabling them to reach a high gain of pumping light. They also have a large surface area to volume ratio of optical fibers, enabling efficient dissipation of the heat they generate. Thus, fiber lasers can function progressively at kilowatts without cooling systems.

2. They Have an Excellent Beam Quality

A fiber laser machine can process different materials since they have excellent beam quality. The materials include mild steel, stainless steel, titanium, and reflective metals like copper and aluminum. These metals make up most of the laser applications worldwide, but they can also process plastics, ceramics, silicon, and textiles.

In most cases, laser beam quality is regarded as how tightly the beam focuses. It is quantified by an M*2 factor which is the highest beam quality. Fiber lasers have the best beam performance and can be used in many applications.

While laser cutting uses fiber lasers, their beam quality allows a longer distance between the workpiece and the focusing object. In addition, the configuration protects the optics from debris and fumes.

Learn more on what laser cutters are used for here.

3. They Have a Smart Feedback Loop

Fiber lasers do not use conventional dielectric mirrors in their optical feedback as they have fiber Bragg gratings. These are a series of glass fibers that occasionally have different refractive indices. The periodic structures reflect the laser beams at specific wavelengths and become the laser cavity of fiber lasers.

4. They Have a Unique Optical Cavity

Fiber lasers are not similar to lasers that have optical fibers. For instance, fiber-coupled diode lasers have optical fibers that are directed only for beam delivery and cannot be used in simulated emissions. Even though fibers are coupled with laser systems, they cannot have superior features to fiber lasers. Fiber lasers have integrated optical cavities with coiled fiber as their gain medium, thus creating a unique and stable optical cavity.

5. They Have a Compact Footprint.

One of the main benefits of using fiber lasers is their compact layout. Their optical fibers are bendable and can be coiled into compact spaces. In addition, since they have flexible optical fibers, you can customize their optical path giving you more freedom to design for specific situations.

Featured Image Credits: buycnc.com