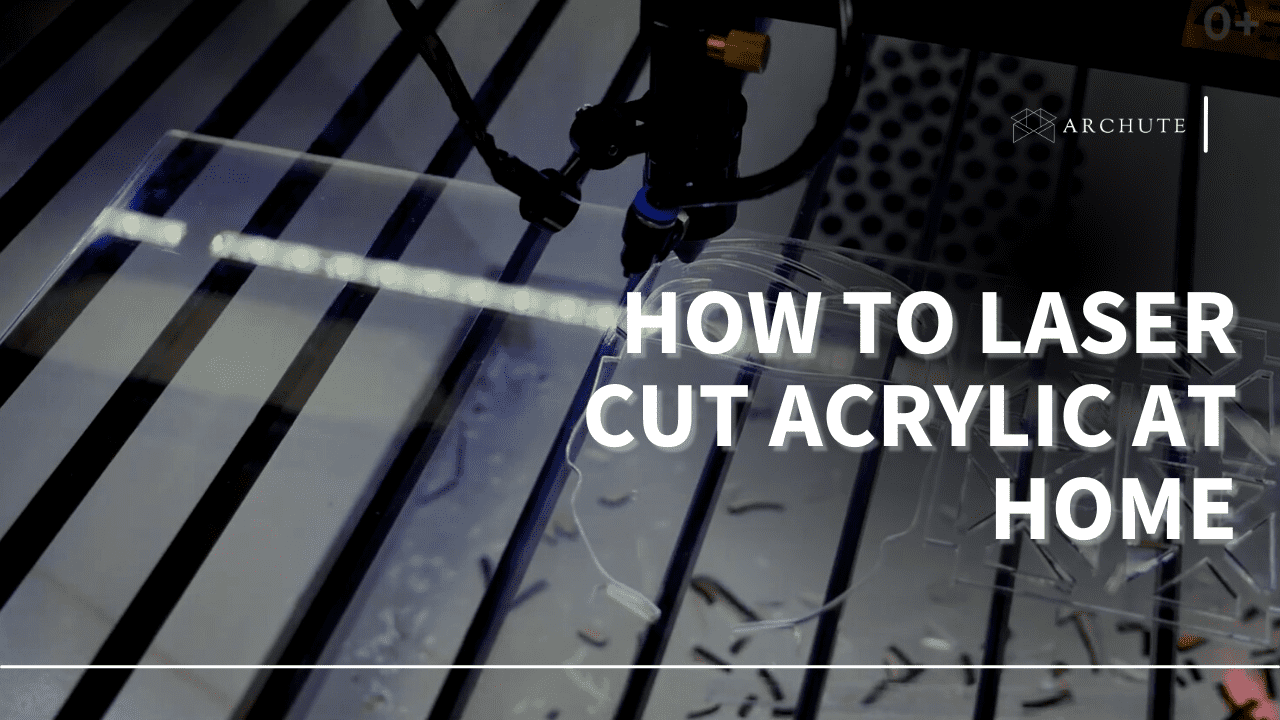

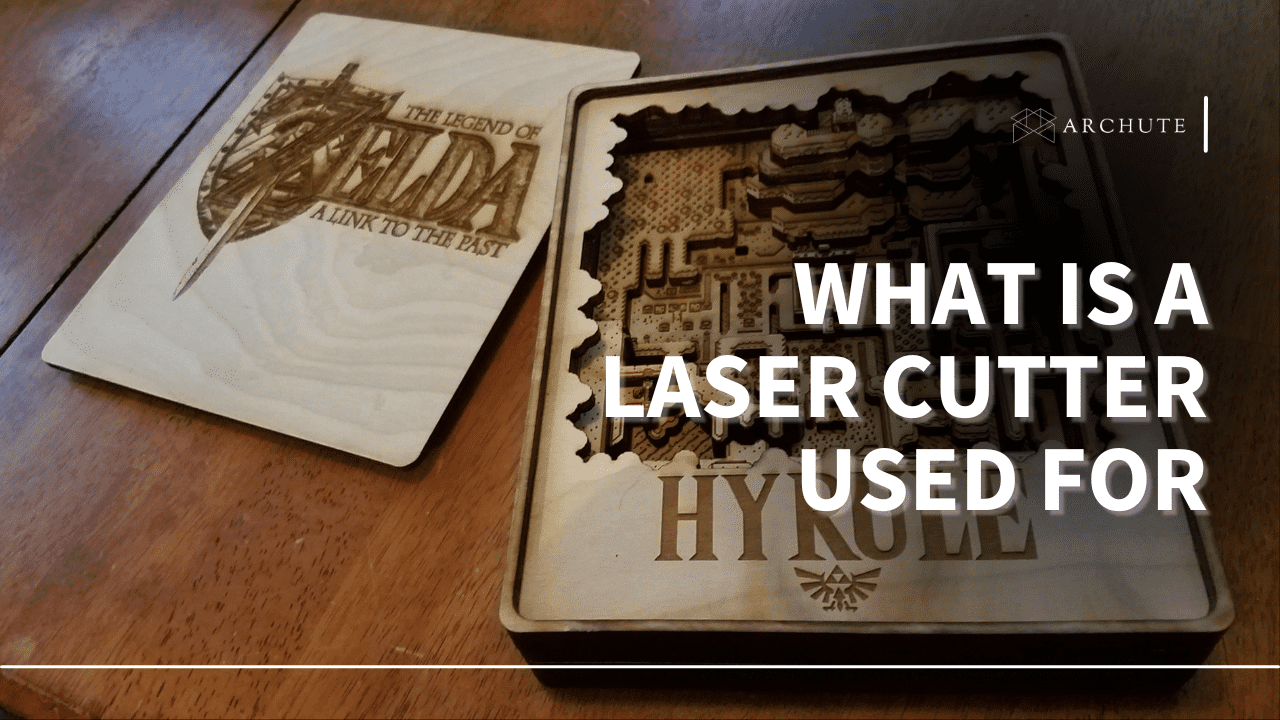

The laser cutting technology has undergone tremendous changes since its inception. Laser cutters, however have become more powerful and accessible and are even available for the hobby user. For example, a designer can draw anything in design software and then transfer it to the laser machines, and they will cut it out according to the drawing with one click. But how do laser cutters work?

What is a Laser Cutter?

This is a Computer Numerical Controlled (CNC) machine that utilizes a laser to vaporize materials in order to produce a cut edge. Although it was initially created for industrial production, today it is used by small companies, designers, and even children in school and at leisure.

Image Source: wikifactory.com

The Laser cutting machines guide the output of a high-power laser, most frequently through optics. Besides, laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. For example, a commercial cutting laser uses a motion control system to execute a G-code or CNC of the pattern to be cut onto the material.

Furthermore, the focused laser beam is directed to the material, which either melts, vaporizes, burns, or is blown by a jet of gas, leaving an edge with a superior surface finish. On the other hand, laser cutting for metals is more precise than plasma cutting.

Now that we know what a laser cutter is let's check out how it works.

How Do Laser Cutters Work

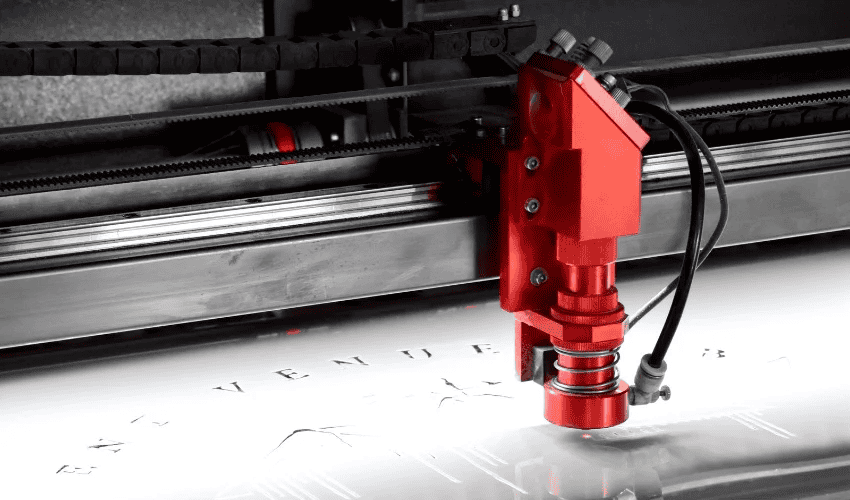

The laser is produced by a laser cavity which is a device that produces a strong light beam that is reflected by a mirror system to the cutting head. The laser is then passed through a lens within the cutting head and pre-concentrated to a very thin beam.

The beam is then focused on the material and can be used to cut the raw stock. The cutting head is often mounted on an XY gantry—a mechanical device with a chain or belt-driven system that positions the cutting head within a rectangular work area the size of the work bed.

Moreover, the XY gantry enables the laser head to travel along the front-and-back, back-and-forth axis of the material surface in order to make cuts at any point on the bed. The laser has to cut; hence, the focal point of the lens must be on the material surface being cut through. Every laser cutter must use a focusing method in order for the laser to cut efficiently.

Laser Cutting Process

When the laser beam gets into contact with the surface, the workpiece material usually absorbs and converts it into heat energy. Then, the heat energy raises the temperature of the material until it melts and vaporizes. There are three laser cutting processes depending on the auxiliary gas used.

1. Flame Cutting

Image Source: freepik.com

In this flame-cutting process (also known as reactive cutting), the auxiliary gas (oxygen) actively participates in the burning and melting of the material. The laser beam usually heats the material while the oxygen reacts with it to generate a fire. This boosts the energy input to the material and helps the laser beam cut through it.

2. Fusion Cutting

In fusion cutting (also referred to as melt and blow cutting), the auxiliary gas doesn't help to melt the material but only comes into play after the laser has melted it. Generally, an inert gas (nitrogen) is used as auxiliary gas to help in the cutting process.

The pressurized auxiliary gas usually blasts the molten metal out of the kerf, boosting cutting speed and minimizing the amount of laser power needed to cut through the material.

3. Sublimation Cutting

Image Source: kasucutter.com

Sublimation cutting (or vaporization cutting) is cutting thin sheets of material without using an auxiliary gas. A high-energy pulsed laser beam often causes material removal in a layer-by-layer manner with no molten pool formation.

What Are the Main Types of Laser?

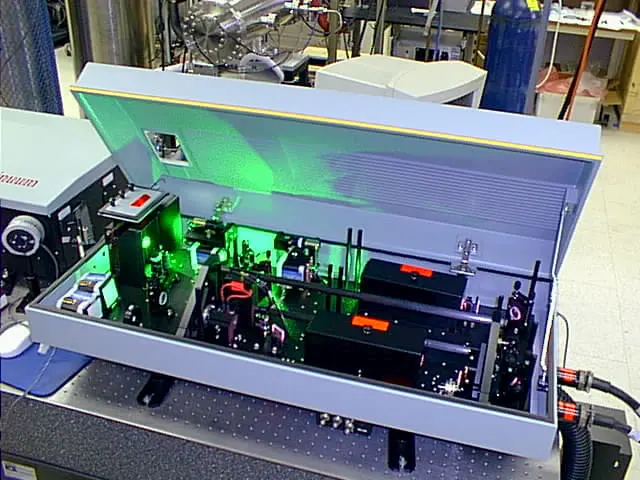

Image Source: physics-and-radio-electronics.com

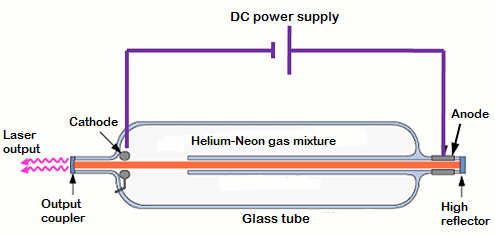

1. CO2 Laser Cutters

A CO2 laser is a glass tube with gas mixture of carbon dioxide, nitrogen, hydrogen and helium. A high voltage electric current is normally passed through the glass tube that excites the atoms of these gases.

Image Source: 3dnatives.com

Then, the atoms emit excess energy in the form of light. This light is reflected between a partially reflective mirror on one end of the glass and a fully reflective mirror on the other. The partially reflecting mirror end produces a high-energy laser beam with a 9,300 - 10600 nm wavelength.

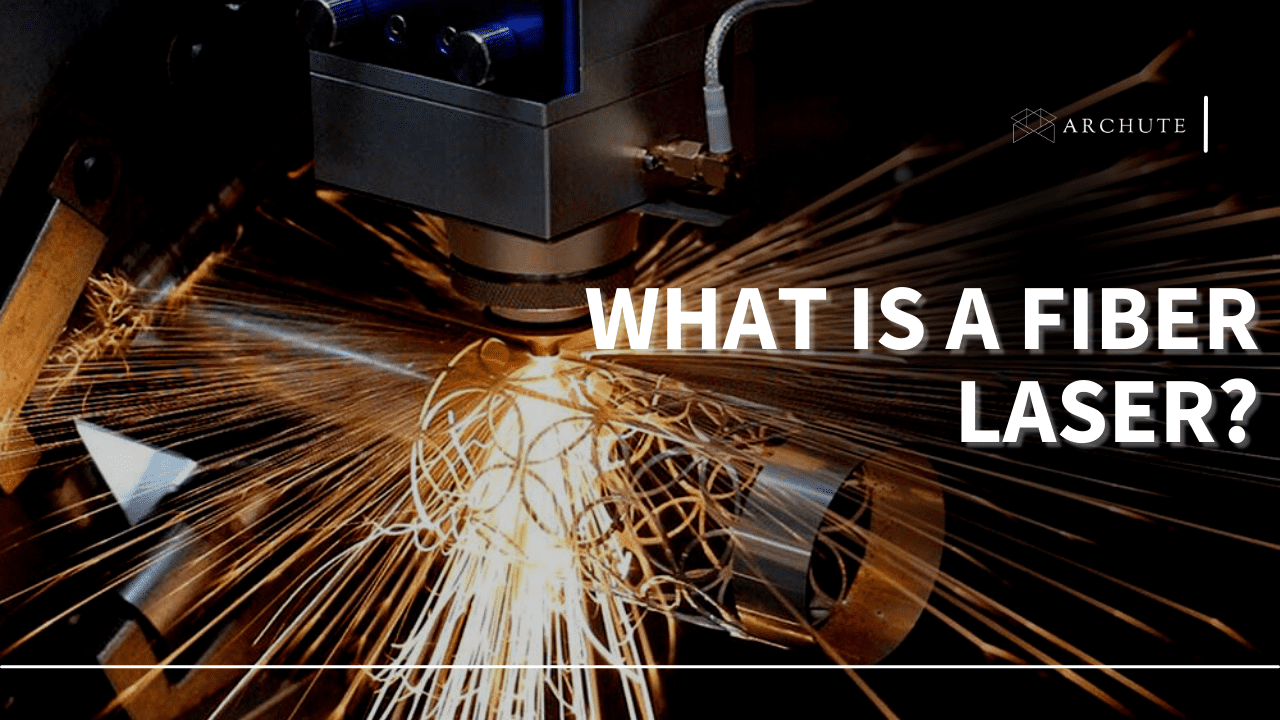

2. Fiber Laser Cutters (DPSSL)

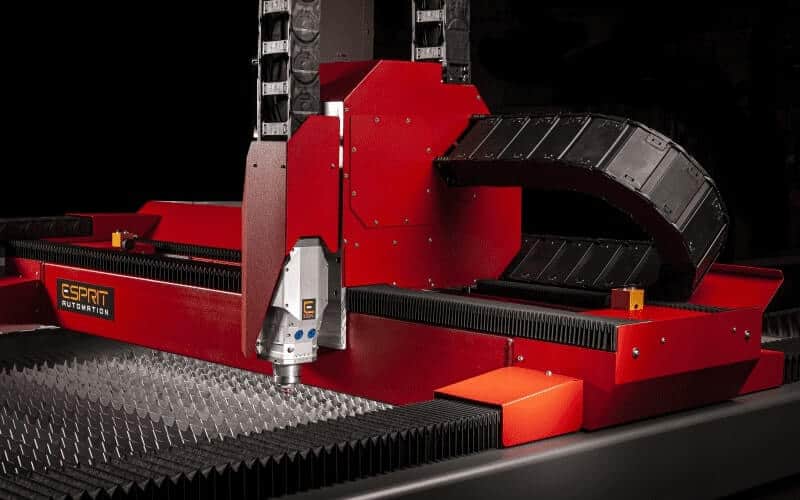

Image Source: espritautomation.com

A fiber laser [also referred to as a solid-state laser (DPSSL)] uses a semiconductor diode to emit light. The light produced by the diode gets into the core fiber, doped with a rare-earth element (erbium, ytterbium, or thulium). Besides, these rare-earth components absorb the light and convert it into the required wavelength laser of 950 nm - 2200 nm).

3. Diode Laser Cutters

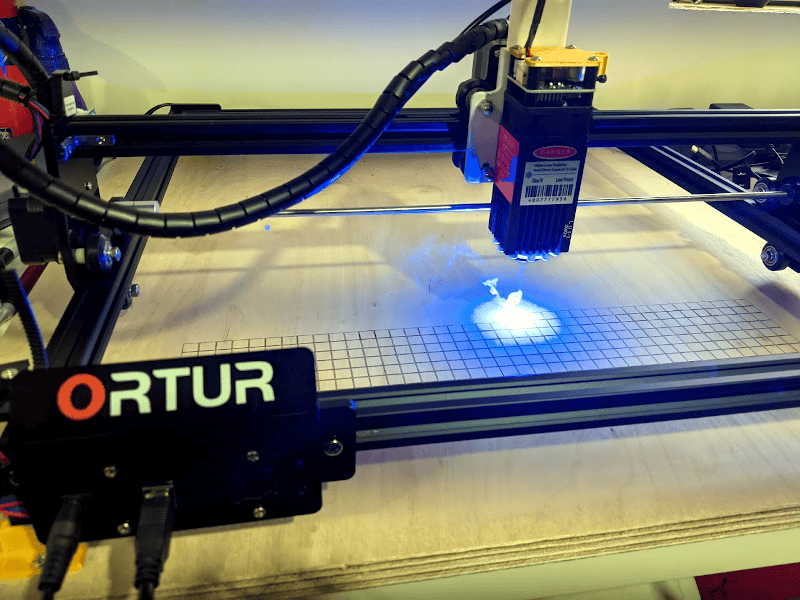

Image Source: ranch-des-troismarie.com

This solid-state laser that directly uses the light generated by a semiconductor diode without a doping medium. This laser is mainly used in low-cost laser engravers with low laser-power output and can cut and engrave thin sheets of materials. However, recent advancements have made it possible to have high-power diode laser cutters that can cut through dense materials.

4. Nd: YAG Laser Cutters

Nd: YAG laser cutter is a solid-state laser made up of an Nd: YAG rod and a krypton arc lamp housed within an elliptical reflector. The light energy emitted from the arc lamp is usually reflected by the elliptical reflector's walls and absorbed by the Nd: YAG rod.

Image Source: fractory.com

This stimulates the Neodymium ions in the Nd: YAG rod, and surplus energy is emitted in the form of bright light. Then, similarly to a CO2 laser, the light is reflected between a partially reflective mirror on one end of the elliptical reflector and a fully reflective mirror on the other. Besides, the partially reflecting mirror end produces a high-energy laser beam that has a wavelength of 1060 nm.

Featured Image Source: ghaniassociate.com