Generators are big, complex power generators that we rely on to keep the world functioning when utility electricity breaks down. But what if your Kohler generator runs, but no power is produced? The loss of residual magnetism in the alternator and a failing AVR or other excitation component are typical causes of a generator not producing power.

Kohler Generator Runs, but no Power is Produced.

1. Loss of Residual Magnetism

Generators work by pushing electrical conductors through a magnetic field that they create themselves. Magnets are not found in generators. Instead, the magnetic field is formed by converting a portion of the generator output voltage to DC and feeding it into a coil to create an electromagnet.

Generators use a phenomenon known as residual magnetism to start up. A small amount of magnetism was leftover from the magnetic field created the last time the generator ran. However, it is sufficient to generate enough power. An electromagnet is made with this minimal amount.

The engine turns this electromagnet, moving its electric field through the stator windings resulting in the generator producing power. Your generator will produce no power upon starting if residual magnetism is removed. You can prevent residual magnetism loss by running your generator with a load and disconnecting that load before turning it off.

The loss of residual magnetism can be caused by:

- The generator is out of service for an extended period.

- Having a connected load when the generator is turned off.

- Running your generator for an extended period with no load.

- Long-distance transportation vibration if you have a new generator.

2. Poor Connections

Clean all ports of any particles, trash, or blockages, and double-check that all connections are secure. It is a crucial step in ensuring your generator's dependability.

3. Blockage or Excitation Circuit Wiring Error

Panel/wiring issues that cause low voltage alerts. If a circuit wiring error is the problem, locate it and fix it. For example, if an excitation circuit is broken, use a multimeter to locate and reconnect the broken excitation winding. If the failure is due to poor contact, you can polish the surface oxide layer until it is smooth, then tighten the loose connection nut and bolt.

4. Tripped Breaker

Before starting the generator again, figure out why the breaker tripped and fix it. If the engine isn't producing electricity, replace the blown fuses/circuit breakers. If the fuse keeps blowing, Kohler suggests inspecting the ground wires.

An electrical short can be caused by faulty ground. The alternator may need to be replaced if the ground connections are securely linked to a metal surface.

5. Broken or Grounded Generator Excitation Winding

Check the ground insulation of the excitation winding with a 500V voltage meter, locate the ground point, then locate and restore the broken winding with a multimeter.

6. Worn Brushes

It is a simple fix. Simply switch out the brushes.

7. Defective Breaker

To avoid an accidental:

- Remove the spark plug.

- Unscrew any screws holding the outlet housing in place.

- Remove the power cord, open the outlet housing cover, and note the wire orientation on the breaker you're replacing.

- Remove the old circuit breaker protective cover by pressing on the tabs with a flat-head screwdriver to release the breaker.

- Finally, reconnect the wires and snap the new breaker into place. Then, reverse the previous procedures to reassemble everything.

8. Defective AVR (Automatic Voltage Regulator)

To avoid any unintentional ignition, unplug your spark plug. Next, disconnect the two spade connector wires from the brush assembly and remove the bolts or screws holding your generator's alternator cover.

You may take a picture to help you remember what goes where. Next, remove the screws that keep the AVR in place, unhook the quick connector, connect the new AVR to the quick connector, and reassemble it as before.

9. Defective Capacitor

Remove the generator's capacitor and discharge any remaining charge. Then, using a multimeter, take a reading from the capacitor. The reading should be within +/- 5uf of the capacitor's indicated rating listed on the side. If it isn't, it needs to be replaced.

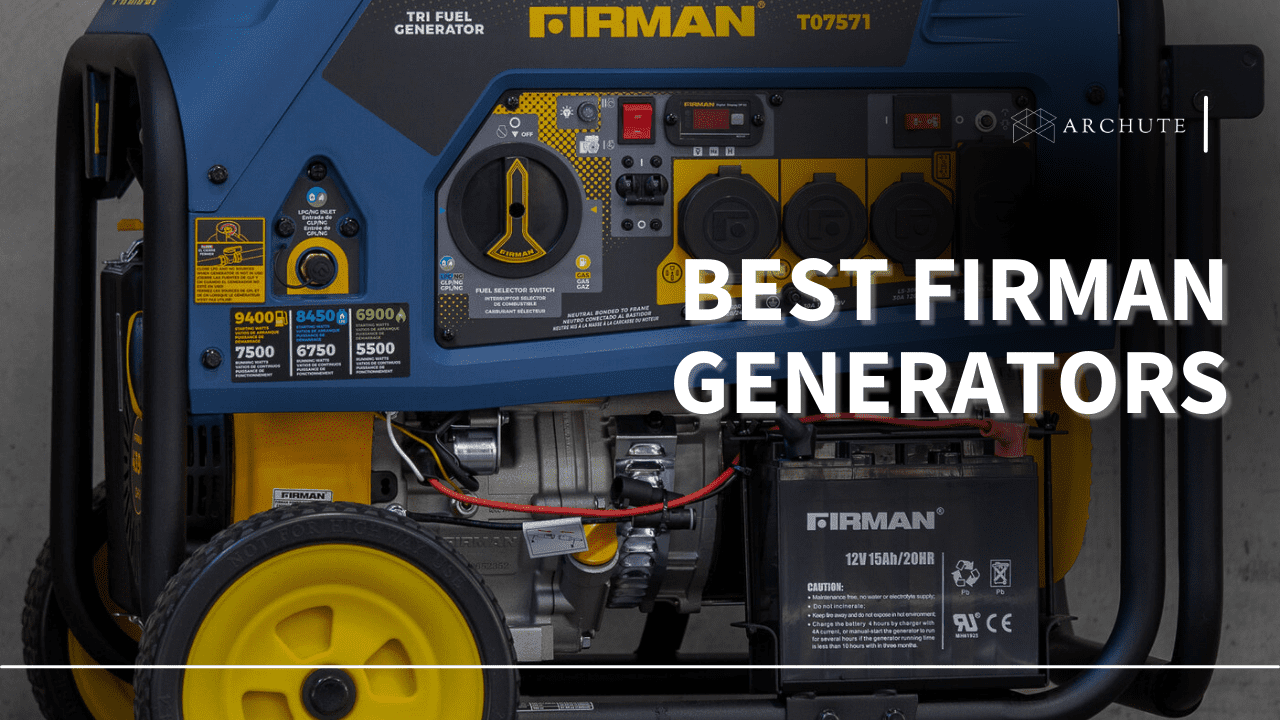

Featured Image Credits: kohlerpower.com