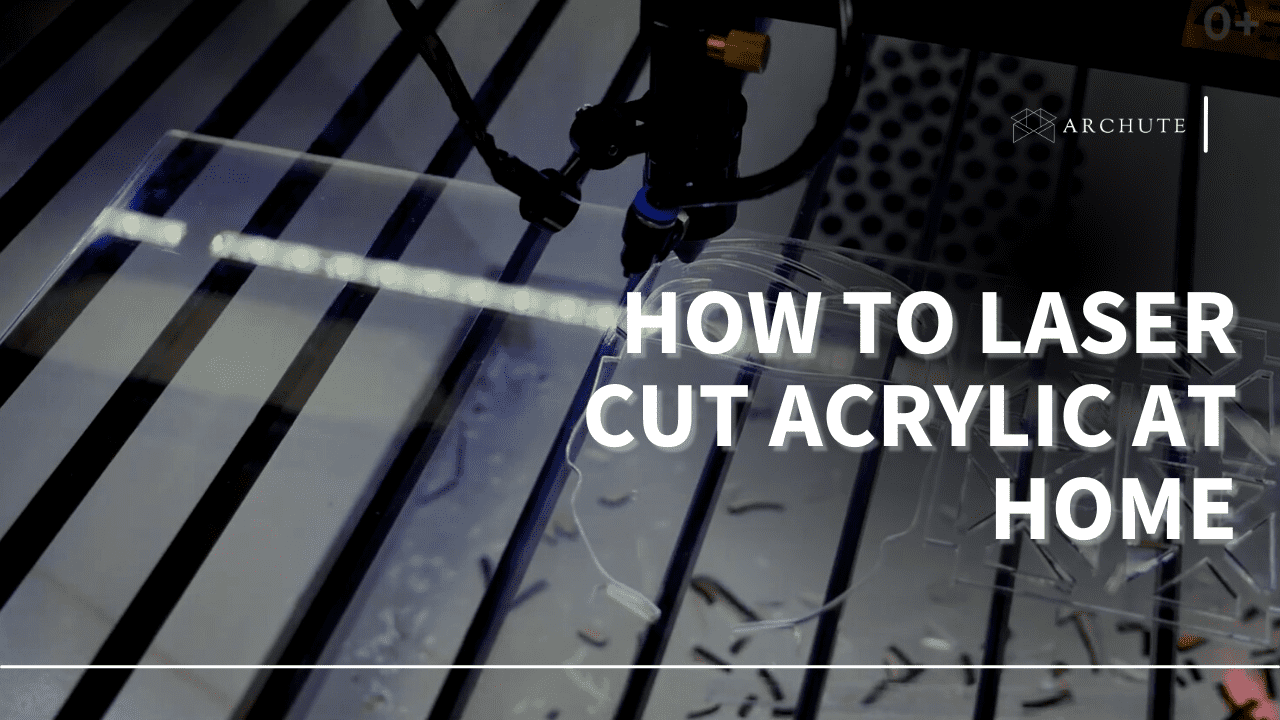

With the innovation of CNC machines, you can now laser-cut almost everything, including Acrylic. This article provides you with details on how to laser-cut Acrylic at home.

Let’s get into it!

What is Acrylic?

Acrylic or Plexiglas is a plastic substance that is translucent like glass with excellent qualities but less brittle and does not break easily. Acrylic comes in various shapes, sizes, and colors and is used for many things, including windows, lights, awards, and other works of art. In addition, Acrylic has a straightforward manufacturing method, making it less expensive than other polymers.

Image credits: pyrasied.com

What is Laser Cutting Acrylic?

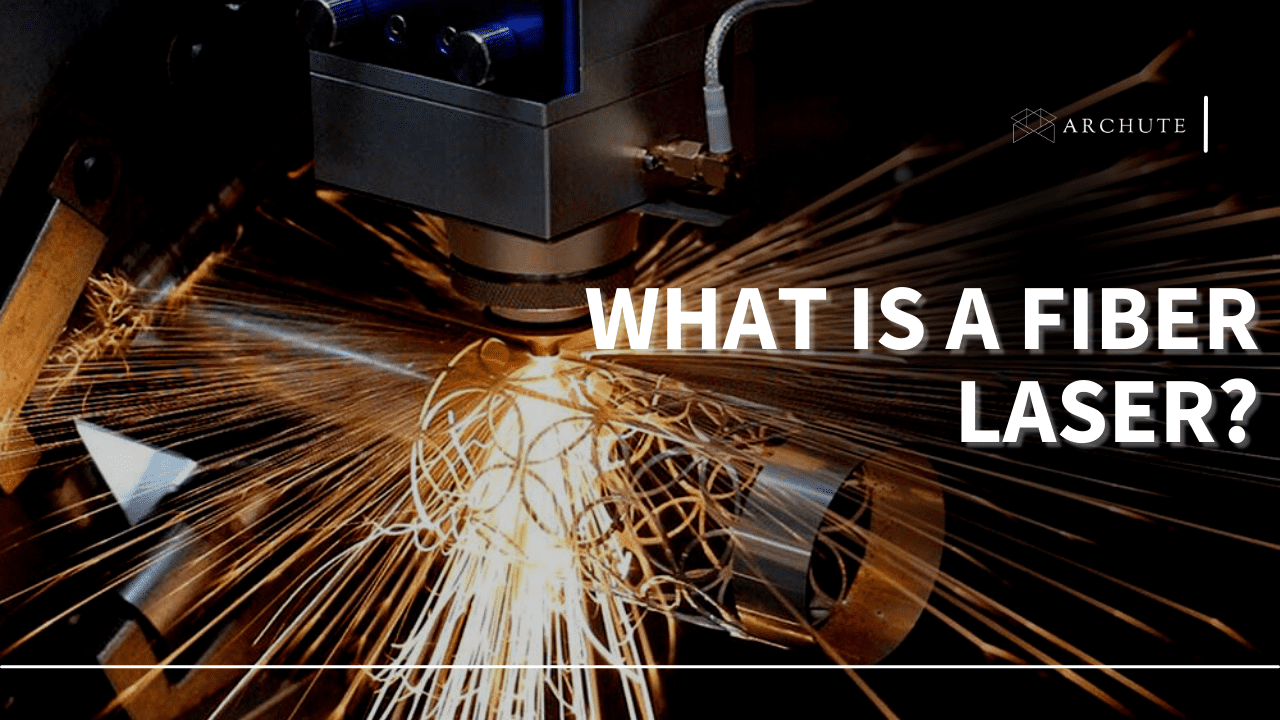

Most industries program CNC acrylic laser cutters for cutting Acrylic. This CNC machine employs axes X and Y to cut items, making them bi-dimensional. The computer and machine must be connected for the acrylic cutting machine to move following orders once operators have transferred the digital file into the computer.

Using a laser beam, an acrylic laser cutting device cuts, fuses, joins, and evaporates materials. High speed and accuracy are the two main components of the acrylic laser cutting machine. Therefore, preparing the proper file is crucial in the Acrylic laser-cutting process. The planned single-line vector file is used as the movement guide for the Acrylic laser-cutting machine.

How to Laser Cut Acrylic

You may set up a tiny workshop in your house and use a laser cutter to cut Acrylic.

Make sure you have the following things before you begin:

- Acrylic.

- Computer.

- A laser cutter.

- Design software.

Since the laser cutter mostly serves as a printer, you must transfer your drawings from your PC to it. The pattern is transformed into a piece of Acrylic after it passes through the laser cutter.

The Process of Laser Cutting Acrylic

You can opt if you need a product that you would use as a mechanical component, making its edge quality somewhat unimportant, or you can pick whether you need a product with a precisely flamed finish.

a) Set Up a Workbench or Table

Make sure you have enough space to work on your project. A suitable workplace is necessary since acrylic laser-cutting technology requires some care. When operating on the project, all the components you need should be on your work surface.

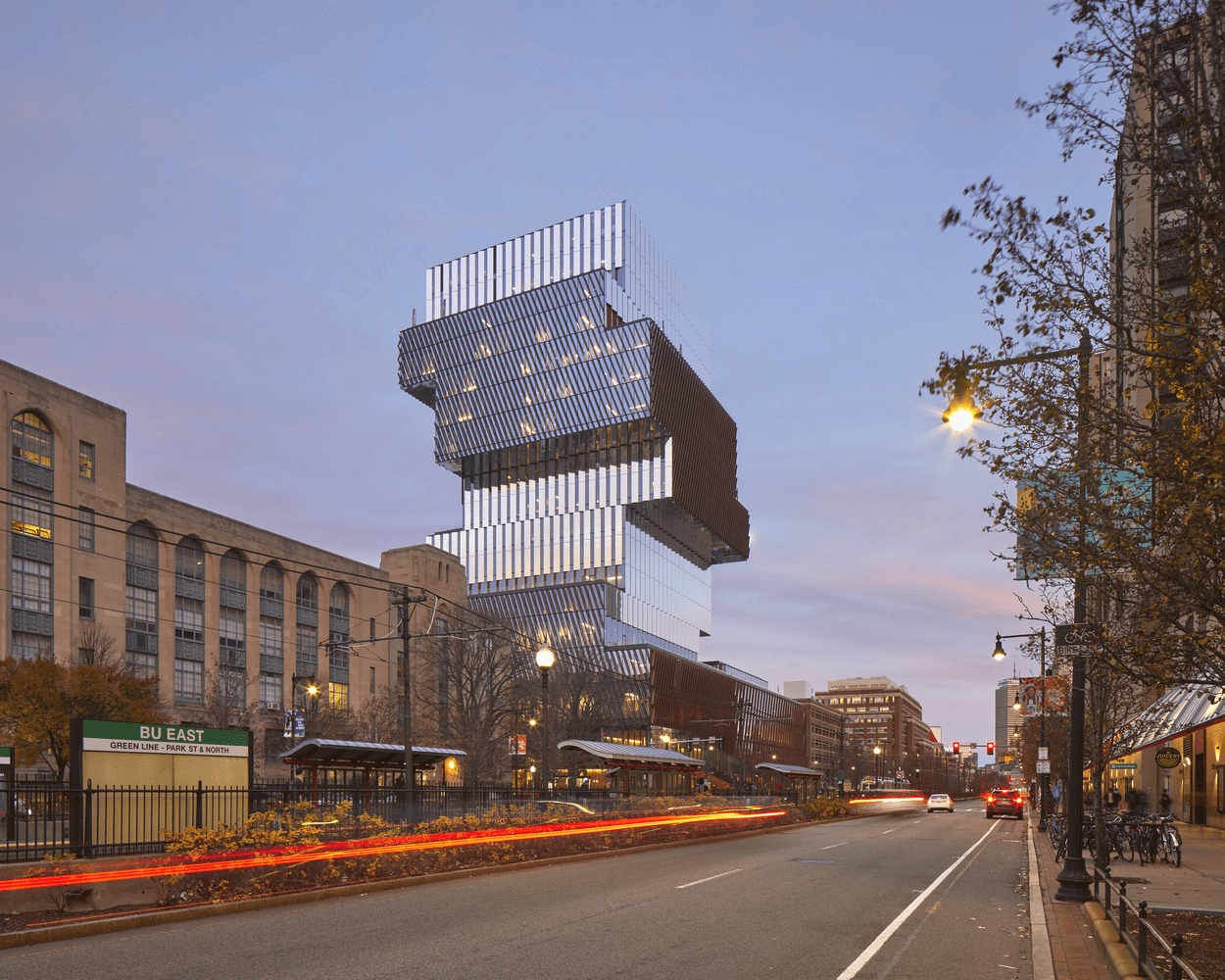

Image credits: unrealengine.com

Additionally, you should set everything up properly to make it simple to carry out various tasks related to the laser-cutting process.

b) Prepare Acrylic Sheets

In this stage, create the picture or pattern on the acrylic material you wish to cut. Now all you have to do is choose the image of the object you want to cut using your computer and the appropriate software. Without a doubt, the program needs to work with the acrylic laser cutter. It is crucial since it makes your task easier overall.

c) Mount the Acrylic Laser-Cutting Device

Before connecting the machine to the PC and starting the cutting process, assemble the machine as necessary. The laser cutters rarely come completely constructed in the majority of situations. However, they come with thorough instructions, making the entire construction process simple.

As a result, you must set it up correctly before beginning the process.

d) Cutting Acrylic Using a Laser

It won’t take much to alter a few parameters once the acrylic material has been cut and properly positioned within the gadget. First, confirm that the equipment’s various parts are functioning properly. Cutting is done by vaporizing the material where the substance absorbs a laser, causing it to change from a solid state to a liquid state and finally to a vapor state. Ensure you have a powerful vacuum system to remove the extra vapor.

Also, remember that the laser-cutting process produces a highly combustible vapor. Therefore, you must always have the laser system under your supervision when cutting the acrylics to maintain the highest safety precautions. Most of the time, a light breeze will blow the vapor from the cutting spot. It is done to stop vapors from igniting. This mild stream of air is essential because it helps the remaining liquid along the incision line to harden.

e) Completion Operations

You may need time to determine whether the outcomes satisfy your expectations once the cutting procedure is finished. In other cases, the product must undergo certain finishing procedures to give it the required appearance and quality.

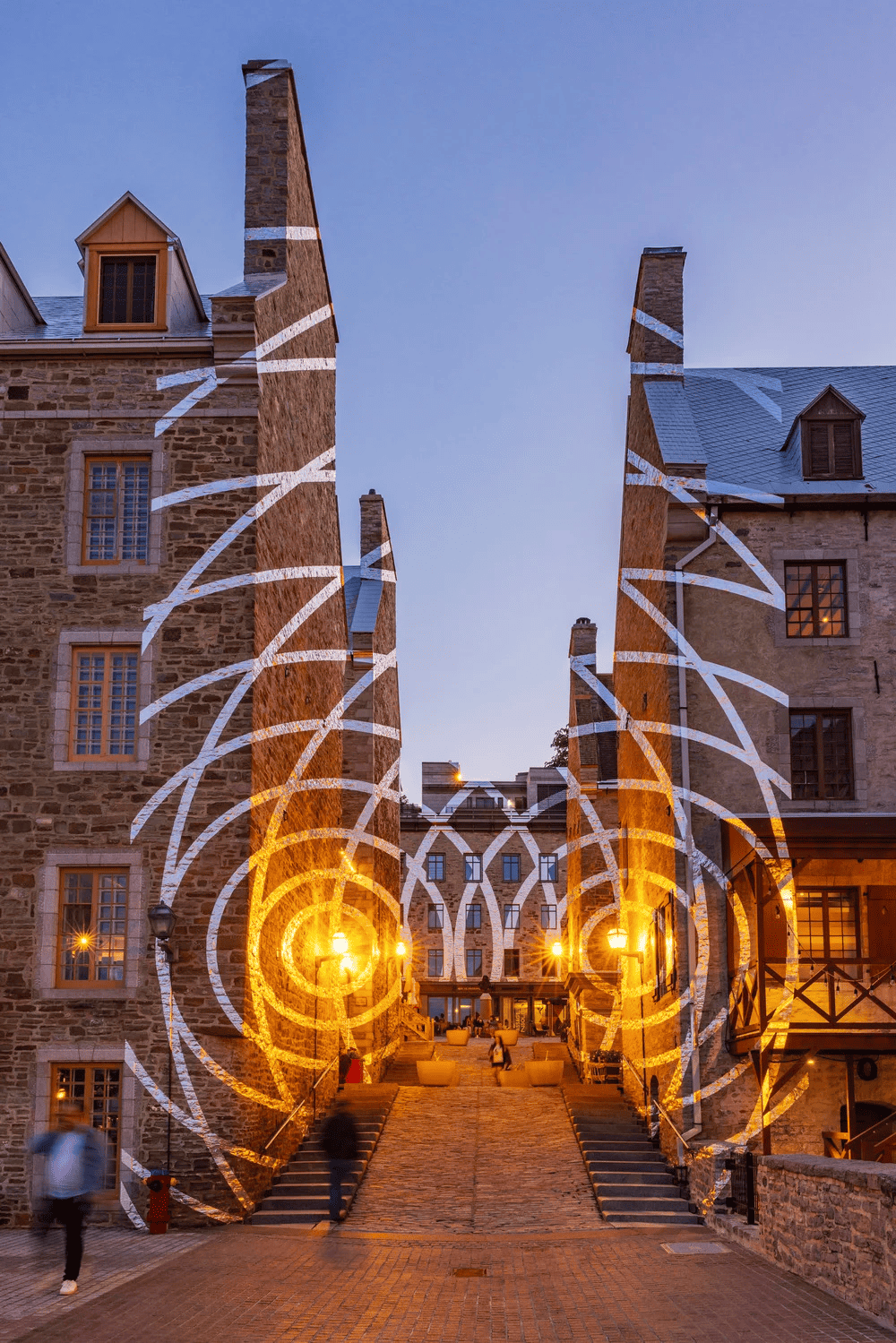

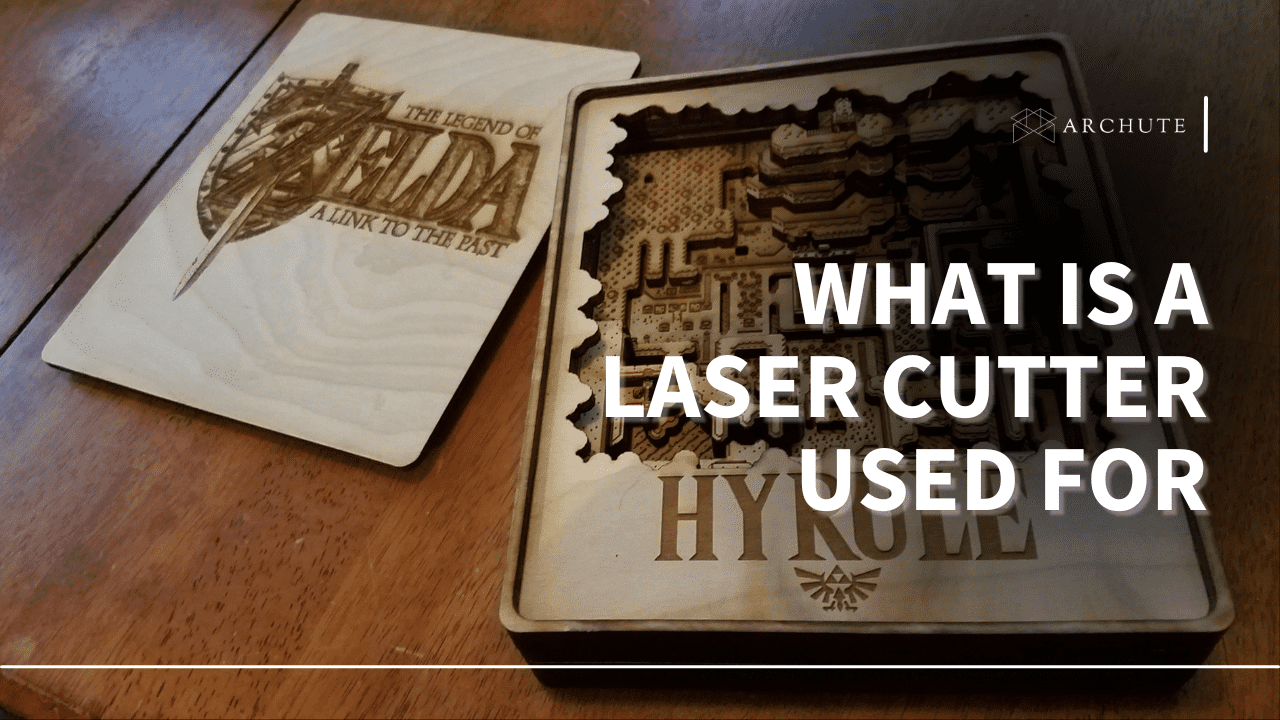

Image credits: wattsan.com

You should include the appropriate components to achieve a glossy, smooth flame-polished finish on the cutting surface. Your final product will be of the desired quality and finish after this process is complete. The ability to run the equipment is crucial, specifically changing the speed, power, and frequency settings.

Tips for General Laser Processing of Acrylic

- Make sure you have the acrylic machine in sight. Many materials may catch fire, but it has been shown that laser-cut Acrylic is explosive in various varieties. Therefore, it would be best if you never operate the acrylic laser cutter when not present while utilizing any material.

- Make careful you pick the appropriate acrylic type for your application. Remember that cast acrylic performs better for engraving and extruded Acrylic performs better for laser cutting.

- To get rid of backside reflection, raise the Acrylic using supports like Epilog’s Pin Table or any elevated surface.

Factors to Consider When Laser Cutting Acrylic

a) Brand or Type

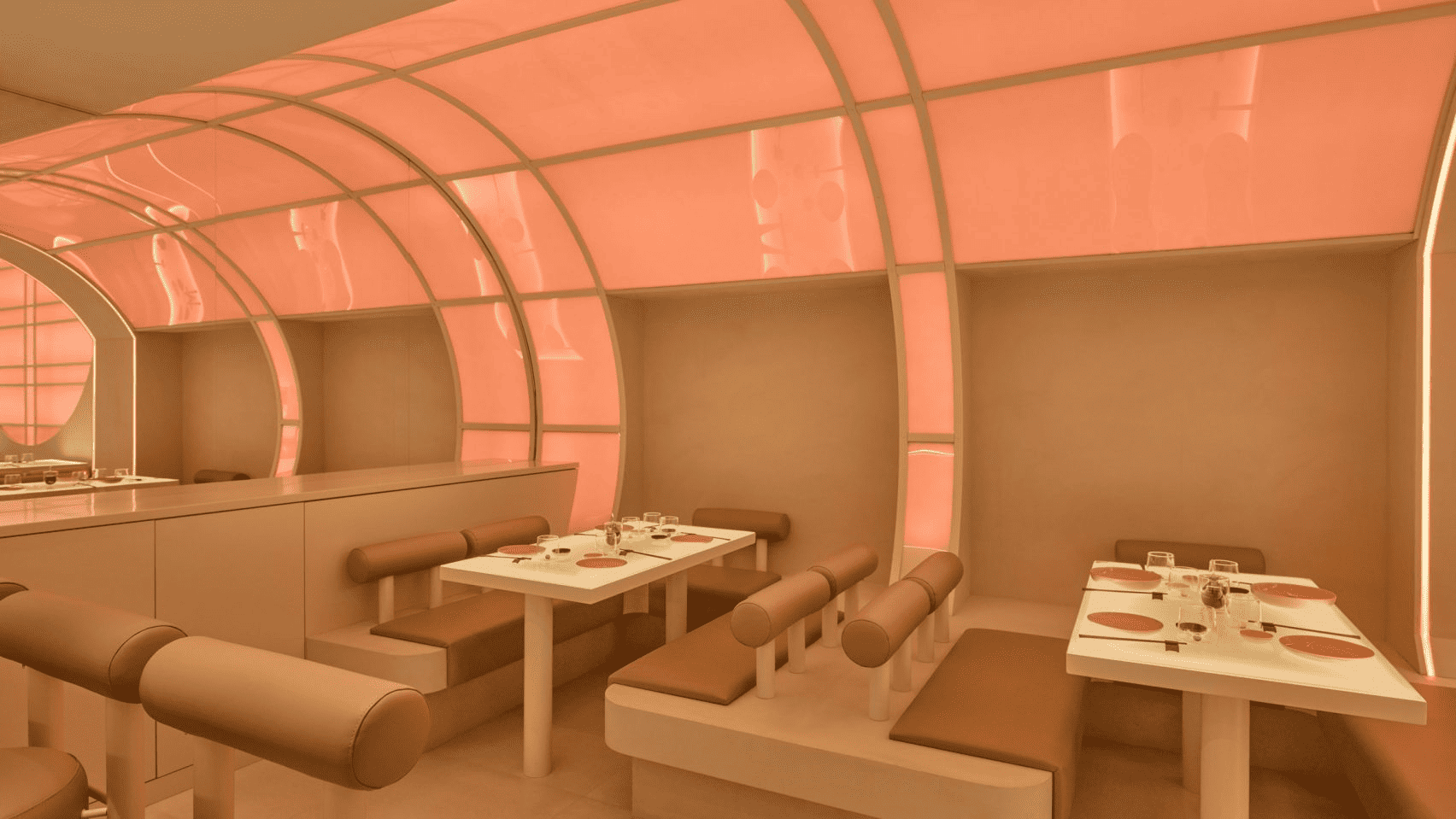

Know the Acrylic Brand or Type Before Cutting. Make sure you use the appropriate type or brand of acrylic material before considering starting this process. These materials are typically offered in two forms: extruded and cast. Therefore, you need to know the kind that will provide the desired outcomes. The brand of acrylic material is another important consideration.

Image credits: all3dp.com

b) Machine

Select the Best Acrylic Cutting Machine. Many machines are on the market, and your specific pick will rely on several criteria, including your budget. If you do not need one or cannot purchase one, keep in mind that you always have the option of leasing one. Always remember that the acrylic machine you decide to buy or rent will greatly impact the results.

Featured image credits: wattsan.com