Ultimately, choose the polycarbonate sheet size that best fits your project needs while taking into account practical considerations such as availability, cutting, transport, and storage. Lexan Margard is a type of polycarbonate sheeting manufactured by a global chemical and plastics company.

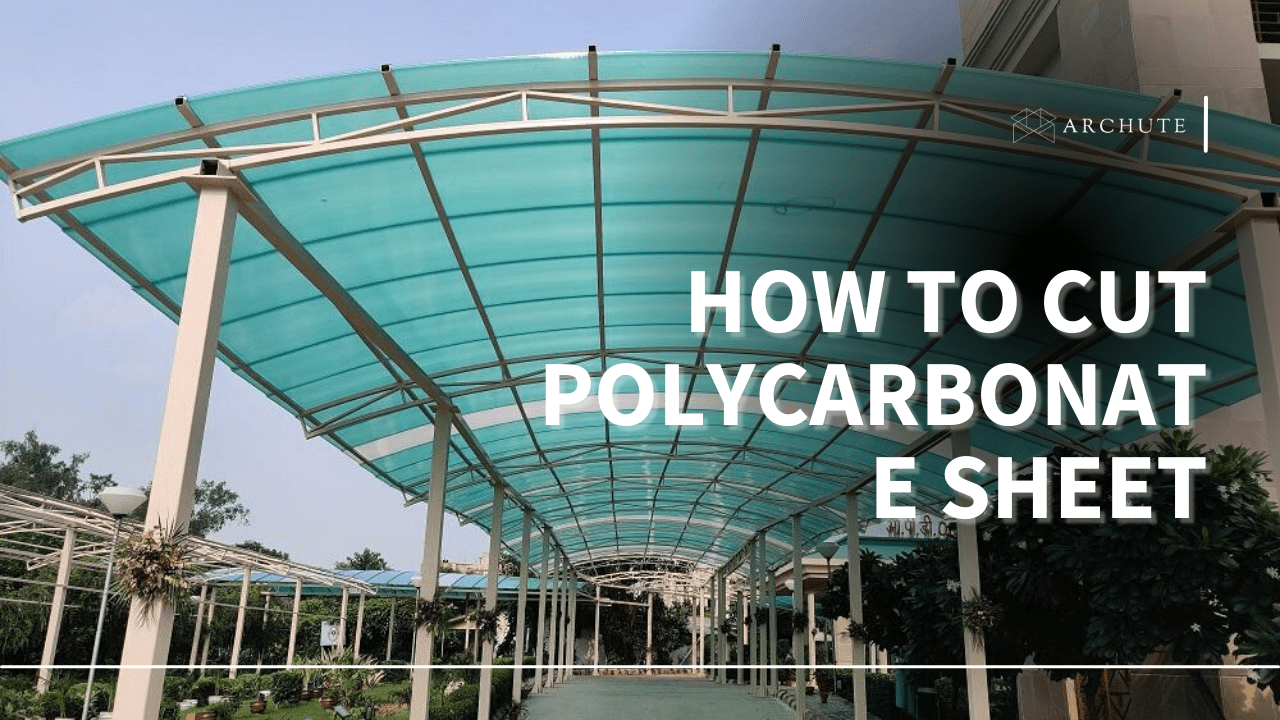

Most customers are often wondering how to cut polycarbonate sheets to the best size, and this article will be a handy guide to achieving the best cuts.

What is Polycarbonate?

Polycarbonate is a sturdy, transparent, and heat-resistant plastic mainly used in greenhouses, eyewear lenses, and automotive components. It comes in sheets of different thicknesses and can be cut using different tools. Although it is very flexible and resistant to blunt force, it is quite simple to cut into sizes.

In addition, since it’s impact-resistant, it has become a popular choice for making protective gear like face shields for saw millers and other manufacturing and construction workers. Its impact resistance ensures it will not shatter, chip, or get damaged by adverse weather. Plastic is also known for its high transparency, toughness, and thermal and dimensional stability.

Different Sizes Of Polycarbonate Sheet

Image Credit: hsqy-plasticgroup.com

Polycarbonate sheets are available in a range of standard sizes but can also be custom-cut to meet specific size requirements. The thickness of the sheets can also vary, with standard options ranging from 2 mm to 20 mm. The thickness of the sheet will depend on the specific requirements of the project, such as the amount of light transmission desired and the strength needed to support the weight of the structure.

When ordering polycarbonate sheets, it is important to measure the area where the sheets will be installed and calculate the total square footage. This will help you determine the size and quantity of the sheets you need to order. Custom cutting and drilling services may also be available from the supplier to meet the specific requirements of your project.

The most common sizes for polycarbonate sheets include:

· 4′ x 8′ sheets

· 6′ x 10′ sheets

· 8′ x 10′ sheets

· 10′ x 20′ sheets

Different Types Of Polycarbonate Sheet

Image Credit: tuflite.com

There are several different types of polycarbonate sheets, each with unique properties and uses. Some common types include:

1. Clear polycarbonate: Clear polycarbonate sheets are transparent and offer excellent light transmission, making them a popular choice for glazing and roofing applications.

2. Frosted polycarbonate: Frosted polycarbonate sheets have a matte finish that reduces glare and provides more privacy. They are often used in skylights and partitions.

3. UV-protected polycarbonate: UV-protected polycarbonate sheets are designed to resist yellowing and degradation caused by exposure to UV radiation. They are ideal for outdoor applications, such as roofing and glazing.

4. Bulletproof polycarbonate: Bulletproof polycarbonate sheets are designed to withstand high-impact forces, making them suitable for security and protection applications such as bulletproof windows and partitions.

5. Multiwall polycarbonate: Multiwall polycarbonate sheets consist of multiple layers of polycarbonate that are laminated together. This gives them superior insulation properties and makes them a popular choice for greenhouse and conservatory applications.

6. Corrugated polycarbonate: Corrugated polycarbonate sheets have a series of waves or ridges that provide additional strength and rigidity. They are often used for roofing and siding in commercial, industrial, and agricultural applications.

Where Polycarbonate Can Be Used?

Image Credit: anandplastics.com

Polycarbonate is a versatile plastic that is used in a wide range of applications due to its combination of strength, transparency, and heat resistance. Some common uses of polycarbonate include:

- Polycarbonate is used for roofing, skylights, and walls in commercial, industrial, and residential buildings.

- Polycarbonate is used for safety glazing in car windows and windshields.

- Polycarbonate is used in medical equipment and instruments, including protective shields, face masks, and goggles.

- Polycarbonate is used to protect electronic components and devices, such as smartphones, laptops, and televisions.

- Polycarbonate is used to make bulletproof and shatterproof windows and partitions.

- Polycarbonate is used in the manufacture of sports equipment, including helmets, goggles, and protective gear.

- Polycarbonate is used to make food and beverage containers, such as water bottles and food storage containers.

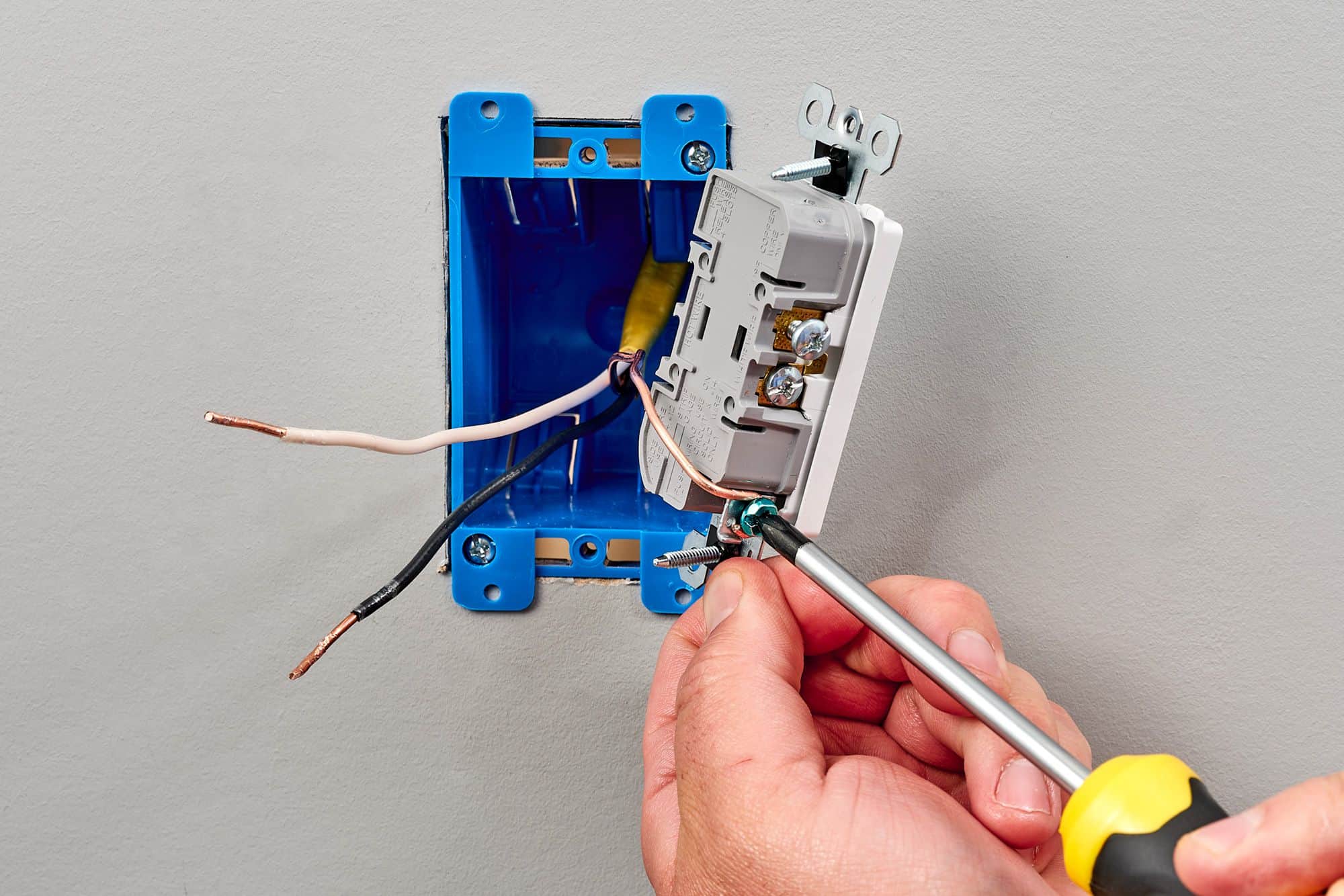

Guide to Cutting Polycarbonate Sheets

Image Credit: youtube.com

What You Will Need

When cutting polycarbonate sheets, there are some things you will generally need, including:

- Cutting tool with an adjustable speed

- Masking tape

- Permanent marker

- Sheet material or wooden clamps for support

- Cutting blade with fine teeth

- Straight edge

- Glue clamps

- Tape measure

- Gloves

Once you have assembled all the materials you need and prepared your working area, clean the saw area to ensure you remove any material that might scratch your polycarbonate sheets.

Before you start cutting your polycarbonate sheet, use a tape measure to measure the cuts you would like to make accurately. Then, mark your cut lines with a grease pencil, dry-erase marker, or a permanent marker.

1. Protect your Polycarbonate

To cut polycarbonate sheets, you need to ensure you maintain the protective plastic coating of the polycarbonate sheet material intact. Wait until you’re ready to install the sheet before removing the thin, clear plastic from it. The sheet will be shielded by thin plastic from potential mechanical harm during the cutting operation.

2. Mark the Cuts

To make the cuts you want to make on the polycarbonate material, use a black marker and tape measure. Make markings at the beginning and end of the cut line. Between the two marks, place the straight edge. To connect the two end locations, draw a small black line.

3. Put on Protection

Put on all the necessary safety gear, including eye protection like safety goggles, gloves, and a dust mask, before you start to cut polycarbonate sheets.

4. Position the Polycarbonate Sheet

Lay the plastic sheets and ensure they are well supported during the cutting process. Use two 2x4s to give support to the plastic sheets on either side of the cut if needed.

5. Prepare the Saw

To make the straight line cuts, put a fine-toothed saw blade in the circular saw. For a 7 1/4-inch-diameter blade, the blade’s tooth count should be between 60 and 80. 3,400 RPMs or less is the needed saw speed.

6. Make your Cut

Use a circular saw, jigsaw, or other power tools with a fine-tooth plastic cutting blade to cut along the marked line. To avoid ruining the polycarbonate sheet, use gentle pressure when cutting.

When you are done making the cut, tap the polycarbonate smoothly to remove any hanging debris, and then peel the protective film and apply your filter tape.

Which Tools can be Used to Cut Polycarbonate?

Image Credit: weetect.com

There are several ways of cutting polycarbonate sheets, and you can also use different tools, including:

1. Table Saw

Image Credit: plasticsheetsshop.co.uk

A table saw is a great tool for cutting polycarbonate sheets with a 0.5mm thickness to give a precise and clean cut for your project. You will have to use a fine-tooth saw blade and run it at a slower speed to ensure you get precise and clean cuts. However, you need to check your blade regularly to ensure it doesn’t need changing.

The cutting process of using a table saw to cut polycarbonate sheets is:

- Measure and mark your cuts on your polycarbonate sheeting

- Frame the marks using masking tape

- Mount your table saw on a fine-toothed blade

- Use the fine-toothed saw blade and cut your polycarbonate sheets by pushing through the saw like you would push plywood

- Be gentle and avoid exerting too much pressure when pushing the polycarbonate panels to avoid cracking

- Repeat this process until done with cutting polycarbonate sheet

2. Band Saw

Image Credit: rocheindustry.com

Another good option to cut polycarbonate sheets is a band saw. It is table-stationed cutting equipment that is easy to use and can cut through any polycarbonate thickness. It has a continuous toothed blade that moves between two wheels, which provides a smooth cutting action.

Set your band saw to at least 2500 RPM and choose the best blade with at least 10 to 18 teeth per inch. Ensure you push the polycarbonate sheets smoothly and seamlessly through a band saw to get a smooth and clean cut.

- Mount your blade on the saw and choose a cutting speed of 2500 RPM and above

- Push your polycarbonate roofing sheets gently through the saw and only stop when you are done cutting

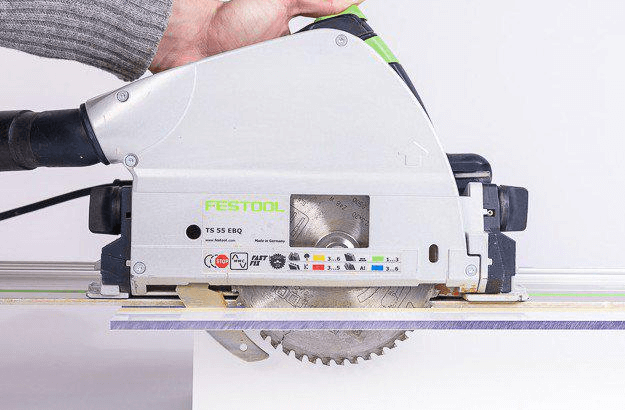

3. Circular Saw

Image Credit: 365plastics.ie

Circular saws are suitable for cutting almost all materials, and they produce good-quality cuts and finishes on the materials they work on. For polycarbonate sheets, a circular saw can cut well through any thickness above 0.125 inches but below 0.5 inches through straight lines.

However, ensure you use a circular saw with a variable speed to allow you to run the blade at a slower speed. Also, it’s necessary to use a guide to ensure you cut the edge as straight as possible.

Set your circular saw at 4000 revolutions per minute to get a smooth cut. This is necessary because the speed of your circular saw will determine your cutting speed, and we would recommend 8 meters per minute to get the best cut.

Notably, cutting thinner polycarbonate sheeting will require you to use a hollow-ground panel blade with at least ten teeth per inch. On the other hand, heavy-gauge polycarbonate roofing sheets will need a triple-chip carbide blade that has alternating bevel and straight teeth with at least three teeth per inch. The process will be:

- Mount the blade you will be using a circular saw

- Clamp your polycarbonate to the saw horse or any other cutting support you are using

- Remove the wood or metal cutting blade and instead install a plastic cutting blade to prevent movement and minimize friction

- Set the cutting speed at 4,000 rpm

- Hold the circular saw with both hands and push it through the polycarbonate roofing sheets to make your cut

- Ensure you use moderate pressure or force when pushing the circular saw through polycarbonate roofing sheets

- Use a vacuum cleaner or hoover to clean up your surface

4. Jigsaw

Image Credit: freepik.com

Although a jigsaw is used similarly to a circular saw, it is the best tool to cut curves and designs from any polycarbonate sheet. It is perfect for anyone who would prefer to cut polycarbonate sheets into complex and extravagant shapes.

However, before you use a jigsaw, ensure you are using the right type of blade. Use a fine-tooth saw blade to prevent the polycarbonate sheet from fraying on its edges, and run the jigsaw at a slow speed as you cut through.

Also, most new polycarbonate sheets come with a protective film over them, which you shouldn’t remove before cutting with a jigsaw. This is because doing so can cause damage to the plastic as you are cutting it.

- Use C-clamps and secure the marked plastic sheets to avoid movement or vibration

- Lay your polycarbonate roofing panels on a cutting surface

- Line the base plate with your cutting line using glue clamps since there is a guideline at the tip indicating where the blade will get in and align the guideline with your marked line

- Press the saw shoe on your polycarbonate and direct the jigsaw blade through it to cut

- Use moderate force when pushing your jigsaw through the polycarbonate roofing sheets

If you are cutting designs and curves, ensure you move your jigsaw blade from the curves to the inside corner and also guide your blade through the marks already made on the polycarbonate roofing sheets. Alternatively, you can use relief cuts to minimize waste when you are cutting through tight curves.

5. CNC Routers

Image Credit: smartroofglobal.com

A CNC router is equipment that uses computer technology to perform cutting tasks on different materials. The router uses computer software known as CAD, making CNC routers capable of producing accurate and exact cuts better than what most manual tools provide.

Routers are usually used in woodworking since the bit can shape edges and sometimes cut pieces of wood and remove waste. Although you can use a router to cut polycarbonate sheets, you will have to use the right type.

- It is necessary to have some basic knowledge of CAD software when you want to cut polycarbonate sheets using a CNC router

- Create an input command into the computer program which will show how the router will cut through the polycarbonate

- Place your polycarbonate on the router table and allow it to run through the desired shapes you have set into the CAD software

- You might need to hold the polycarbonate sheeting on the table as the router is doing the rest of the work.

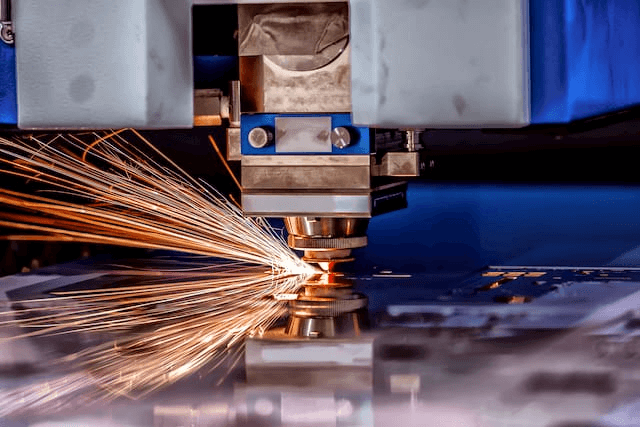

6. Laser Cutting Machines

Image Credit: rocheindustry.com

Lasers are powerful optical beams used to cut through different materials such as wood, metal, glass, and polycarbonate. However, laser cutters come with some complications when compared to other cutting tools.

To start with, laser cutters are expensive, and it’s unlikely that a DIY enthusiast will have one in their collection. Also, a laser cutter will create heat, which is not the best choice for cutting polycarbonate sheets as it can cause the material to get discolored.

Most professionals will even advise against using a laser cutter, and with the range of other cutting tools available, it’s better to consider other options first.

- Mark your polycarbonate roofing sheets to indicate how you would want to cut it

- Place your polycarbonate roofing sheets on a surface you don’t have a problem cutting or you can clamp it to avoid cutting through the surface

- Direct laser beams through polycarbonate roofing sheets following the marked line that you want to cut

- If you are cutting through thicker polycarbonate roofing sheets, adjust the intensity of the beam

7. Angle Grinders

Angle grinders are compact, handheld devices with grit on the cutting wheel. Although angle grinders rotate more quickly than circular saws, their cutting mechanism is very similar to that of sawing. An angle grinder can be used to cut polycarbonate sheets.

- Wear your protective gear

- Use a measuring tape, measure and mark your cutting line on the polycarbonate panels

- Clamp the polycarbonate panels on a raised and stable surface

- Turn on your power tool and wait for it to pick up the appropriate speed

- Cut the panel by carefully moving the angle grinder along the cut line you marked farther away from you

Factors to Consider When Choosing Polycarbonate Sheet Sizes for a Project

Image Credit: hunker.com

When choosing polycarbonate sheet sizes for a project, consider the following factors:

1. Application

Determine the size requirements based on the specific use of the sheet. For example, for a roof, consider the dimensions of the area to be covered.

2. Availability

Consider the standard sheet sizes available from your supplier and select the one that most closely fits your requirements.

3. Cutting

If standard sheet sizes do not fit your requirements, you may need to have the sheets cut to size. Determine if the supplier offers cutting services and if they are within your budget.

4. Transport

Consider the size of the sheet when determining the size of the vehicle you will use to transport it. Larger sheets may require a larger vehicle or may need to be transported in pieces.

5. Storage

Think about how the sheets will be stored before and after installation. You may need to consider storage space and the ability to maneuver large sheets.

How To Choose The Right Polycarbonate Sheet For A Project?

Image Credit: justpolycarbonate.com

1. Specific Use

When choosing the right polycarbonate sheet for a project, consider the specific use of the sheet, such as roofing, glazing, or protective shields. This will determine the thickness, strength, and type of polycarbonate required. Think about the environmental conditions the polycarbonate will be exposed to, such as temperature, UV radiation, and wind. Some types of polycarbonate are specifically designed to withstand harsh weather conditions.

2. Level of Transparency

Choose the degree of transparency based on the intended use of the polycarbonate. Clear polycarbonate provides maximum transparency, while frosted or opaque polycarbonate can offer more privacy or protection from UV radiation. If the polycarbonate will be exposed to direct sunlight, choose a sheet with built-in UV protection to prevent yellowing and degradation over time.

3. Budget

Consider your budget and the cost of the polycarbonate sheets, as well as any additional costs for cutting, drilling, or delivery. Choose a reputable supplier with a proven track record of providing high-quality polycarbonate sheets. Check for customer reviews, warranty information, and the availability of after-sales support.

What are the Safety Precautions when Cutting Polycarbonate Sheets?

Image Credit: tuflite.com

Cutting polycarbonate sheets is generally safe, but observing some precautions can be beneficial. Some safety precautions you can observe include:

1. Wear Appropriate Gear

Wearing appropriate gear for cutting polycarbonate is necessary since sawing the polycarbonate sheet material produces chips and dust particles that can cause bodily injuries. You can also wear gloves to protect your hands.

2. Use a Dust Mask

The dust that comes from cutting a polycarbonate sheet can cause breathing problems and lung issues, and a dust mask will help to reduce exposure.

3. Wear Safety Goggles

The chips and dust from the cutting process can cause permanent eye injuries, so it’s important to consider wearing safety goggles.

4. Test Equipment

Lastly, it’s a good idea to test any equipment you intend to use and check the conditions of your saw blades to ensure they are well-sharpened and are not damaged or corroded. This is beneficial to avoid getting injured if your saw snaps or slips when cutting polycarbonate sheets.

This also applies to any other power tools you will be using. Ensure they are fully functional, clean, and not making any weird noises.

Conclusion on How to Cut Polycarbonate Sheet

Polycarbonate sheets are available in a range of standard sizes but can also be custom-cut to meet specific size requirements. The thickness of the sheet will depend on the specific requirements of the project, such as the amount of light transmission desired and the strength needed to support the weight of the structure. It is a high-quality, durable, and versatile material that can provide long-lasting protection and performance in a variety of applications.

Frequently Asked Questions on How to Cut Polycarbonate Sheet

Image Credit: residencestyle.com

1. How Can you Polish Polycarbonate Rough Edges?

While cutting a polycarbonate sheet may get you your desired material size for your project, it might leave you with rough-cut edges. The level of roughness will depend on the cutting method you use, and polishing can help to smooth the polycarbonate roofing sheets and achieve a clean finish.

A polished finish looks more professional and appealing. Buffing is therefore the most effective method for removing serrated, harsh, and rugged polycarbonate edges.

You should use wheel buffing, as this technique makes use of a buffing machine with wheels. These devices are well known for performing their tasks very effectively and leaving your edges tidy and smooth.

2. Does Sheet Thickness Matter?

Yes, since polycarbonate roofing sheets come in a range of thicknesses, it could be easier to cut thicker polycarbonate panels with power tools. Thinner polycarbonate roofing sheets are easier to cut, even with hand tools, but thick polycarbonate panels will often need power tools. Both the solid and multiwall polycarbonate sheets will be tricky to cut using hand tools if they’re thicker than 5 mm, which can still be done but will take more time.

The amount of insulation you need must be carefully considered. Depending on how much additional heating is present in the space, thicker multiwall polycarbonate can be needed. Polycarbonate sheets come in a wide range of thicknesses to meet a variety of needs. Here are a few of the preferred options:

- 4mm polycarbonate panels for greenhouse, sheds, and cold frames

- 10mm polycarbonate panels for pergolas, carports, and sheds

- 25mm and 35mm polycarbonate panels for conservatory roofs

3. How to Cut Polycarbonate Sheets based on Thickness

a). Cutting Thin Polycarbonate Sheets

Using a fine-toothed saw blade is the most appropriate method for cutting thin polycarbonate sheets. These tools provide you with complete control, enabling you to cut your sheets precisely and securely.

More importantly, they are reasonably priced. The sheets can also be scored with a tool and snapped with bare hands. If the budget permits, another option is to use CNC or plasma cutters for intricate patterns.

b). Cutting Thick Polycarbonate Sheets

The best tools for cutting thick polycarbonate sheets are circular saws. They are strong, long-lasting, and appropriate for big projects. Circular saws are also cost-effective. Any metal cutting blade will work. Apart from circular saws, you can consider using a jigsaw, band saw, or plastic laser cutter instead of circular saws.

c). Cutting Polycarbonate Roofing Sheets

For cutting polycarbonate roofing sheets, jigsaws and circular saws work best. A clamp or vice should be used to firmly bind the sheets after marking the cut lines using an erasable marker.

Next, cut carefully to prevent sharp edges. For small projects and DIY tasks, an alternative blade has fine teeth. The best outcomes come from sharp blades.

d). Twin Wall Sheet

Twin-wall polycarbonate sheets are thicker and more durable than regular polycarbonate sheets because they have two polycarbonate layers and an additional layer of plastic for support.

Therefore, you need an even more powerful cutting tool. Your best options are jigsaws and circular saws. However, a handsaw is another option.

4. Is a Polycarbonate Sheet better than an Acrylic Sheet?

Although there are many similarities between polycarbonate and acrylic, there are some differences between the two materials as well. However, polycarbonate has a far higher impact resistance than acrylic, making it perfect for demanding applications like bulletproof windows.

On the other hand, polycarbonate is more durable than acrylic, which is a robust plastic substance in general. While polycarbonate is easier to scratch, acrylic is more brittle.

5. Can I Drill Holes in Polycarbonate Sheets?

Polycarbonate sheets are easier to drill holes in than plexiglass sheets. Both a standard steel drill and an HSS drill are acceptable. Ensure the drill isn’t brand new, though. A brand-new drill’s sharpness has the potential to tear the sheet by biting through it.