Pipes can be quite noisy despite being an essential component of every home because they are the perfect environment for reverberation. For instance, the pipes and the wall cavity concealed are hollow, which is ideal for transmitting sound waves.

Here you will find more details on piping vibrations.

What Makes Drain Pipes Noisy?

Image Credits: brothers plumbing

The water supply system is typically the source of noises you hear from your pipes. The sound from soil and drain pipes can enter the occupied space directly from the pipe's surface when the pipe is not isolated from the surrounding surfaces of the building.

These noise levels can be greatly decreased by properly repairing the waste pipe. For instance, using CIPP lining is the best solution for repairing old, broken, and leaky pipes without digging.

Here are some typical plumbing system noises and the causes of those noises:

1. Rattling Pipes

Image Credits: Mr plumber Atlanta

Most homes have plumbing that runs through the walls and ceilings, moving wastewater outside of the house or providing fresh water as needed. The pipes are supported during installation by strapping fastened to wall studs, ceiling joists, and floor joists. However, as water flows through the pipes, they may jiggle if the strapping loosens.

If this is ignored for too long, the pipes may leak or even burst. A plumber will find the straps to fix the issue and either tighten, replace, add more, or do all of the above.

2. Flowing Water

Image Credits: gsm plumbing

It is not unusual to hear the water moving through the plumbing system, especially in older homes where it was typical to keep drain pipes exposed in the ceiling of a garage or basement.

3. Water Hammer

Image Credits: linquip

Hydraulic shock or water hammer is a loud bang or breaking sound inside the walls. The sound is produced when water rushing through the pipes is abruptly stopped or shut off and collides with the valve.

Plumbers typically repair this issue by adding a pipe called an air chamber nearby the relevant fixture or faucet, which frequently serves as a shock absorber. The air in the air chamber dampens or absorbs the sound of the rushing water, which silences it.

4. Temperature Change

Image Credits: water master plumbing

When you use the hot water, you occasionally hear a clicking or popping sound inside the walls. This is because as the pipe warms up from the hot water, it expands and makes a noise. Most PVC pipes are involved in this situation because they are more likely to expand due to heat.

Call your plumber right away if you hear weird noises in your plumbing and are unsure if they are normal or worried about the energy efficiency of your hot water system.

Here is the best water heater expansion tank for an efficient plumbing system.

This blog post focuses on how to soundproof a drain pipe since pipes are a significant source of noise pollution in many households. The best ways to soundproof a pipe in your home are listed below.

How Much Does It Cost To Soundproof A Drain Pipe?

Image Credits: sound seal

The cost of soundproofing can be affected by a variety of factors. The most important considerations are the size of the job, the kind of material you're employing, and how much you'll need. Hiring a professional increases the cost, but the task is completed quickly and safely.

The price of pipe insulation and soundproofing per linear foot ranges from $1.10 to $11. Materials range from $0.20 to $3 per linear foot, and labor costs between $0.90 and $8 per linear foot. As a result, the price range for an insulation and soundproofing project of 100 feet is between $110 and $1,100.

Soundproofing Pipes During Initial Construction

1. Plastic Pipes

Image Credits: tthme

One of the main reasons why certain installations sound louder than others is the type of material chosen for the drainpipe. Plastic pipes are favored by many plumbers in the modern world even though they are not particularly quiet.

This approach has several benefits, including a lower cost and a simpler installation process. However, despite all these benefits, a plastic drain pipe is quite noisy compared to other materials.

However, that extra noise may not matter all that much if placed in the right places. First, there must be space between PVC pipes since they tend to expand when exposed to hot water and contract when exposed to cold water.

2. Cast-iron Pipes

Image Credits: home inspection insider

Cast-iron drain pipe is among the greatest materials to utilize for a drain pipe from a sound perspective. In addition to being long-lasting, there is a noticeable difference in the sound. The disadvantage is that it is more expensive and more difficult to replace or repair should that ever be necessary.

3. Mix the Drain Pipe Materials

Image Credits: tthme

Fortunately, there is a way to mix materials to regulate sound to a respectable extent. It may not be practical to use cast iron for the entire drainage system as it is expensive. Plastic drain pipes may make sense for most drainage systems until they get close to housing areas. Therefore, only a tiny portion is cast iron-based rather than the entire structure.

4. Copper Pipes

Image Credits: NY-engineers

Copper piping doesn't react well to temperature changes. Hence they frequently produce noise. Additionally, it frequently rubs against nearby pipes when transporting hot water, making an unappealing clanking sound.

5. Location

Image Credits: self-build and design

Placing a drain pipe in the proper location can greatly improve the overall sound if it is a new setup. For instance, the difference it makes to route a drain pipe through a closet wall instead of one that links to the living room may surprise you.

Having a small amount of privacy from the main living space is crucial. Most of the walls in modern construction are fairly hollow. Thus it will be audible if a drainpipe is just behind one of those hollow walls.

How to Soundproof Old Drain Pipes In Wall Cavity

Image Credits: soundproof cow

1. Determine the Wall Cavity

By listening to the sound, determine the wall cavity where the noisy pipe is located. You could also utilize the opportunity to locate any pipes that are making noise by turning on the heating or the faucet.

2. Find the Wall Studs

Find the wall studs on either side of the piping using a stud finder. Make a mark approximately an inch from the end of the cavity once you've located the stud's edge. Hopefully, this serves as a marker for the support joist's middle.

Here is the best stud finder to locate wall studs at home.

Image Credits: Alibaba

3. Make Triangle Marks

Use these points to make marks below the ceiling and above the floor. This will indicate where to mark the drywall piece that you will cut away, which should be around 12 inches from either.

Locate the center point and draw a line to meet the mark 12 inches from the ceiling using the marks you made on the joists.

Then connect the joist marks to the top of this center line. The triangle you wind up marking on the wall will serve as the cutting section.

4. Cut the Triangle

Just cut the triangle out. Since the surface is too thin to require a saw, it is easiest to do this using a craft or drywall knife. You can also avoid the pipes because you have more control over how deep the cut is made.

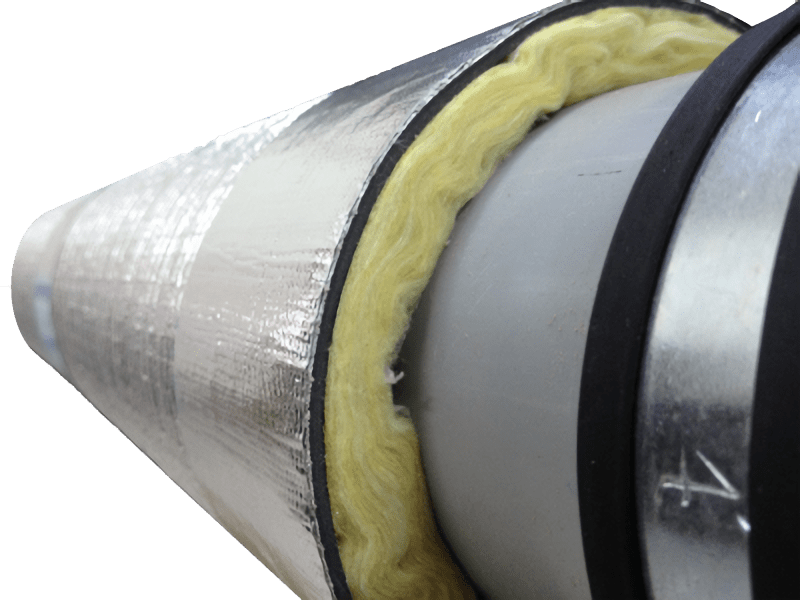

Image Credits: insulation victoria

5. Acoustic Lagging

The exposed pipes should be in front of you once the drywall has been removed. Use cable ties to hold the acoustic lagging as you wrap it around the pipes.

Then nail the piece of drywall to the studs, and fill any cuts with drywall filler. Paint over the necessary areas after it has cured, sand it down so the seams are hidden.

This approach is a little messy, as you can probably see, but it works. Simply ripping out all the drywall and revealing every pipe in the space is much simpler. Despite the possibility that not all of your pipes will be noisy, soundproofing them all at once is a simpler and more practical approach.

Image Credits: national economy plumber

6. Seek Help When All Else Fails

Soundproofing is generally a pretty easy fix as long as there are no structural issues with the pipe. It's a rather simple process; with the correct tools and effort, you can produce some decent outcomes. But if things get a bit too complicated, don't be hesitant to ask a professional for help.

What is the Best Pipe Soundproofing Material?

1. Acoustic Lagging

Image Credits: eco life solutions

Acoustic lagging performs best for noise reduction due to its capacity to absorb sound and produce a cushioned barrier against the wall cavity. Most acoustic lagging is constructed from laminates of dense materials, which add weight without taking up much room. As a result, the sound is absorbed and kept from penetrating support joists or wall cavities.

Numerous varieties of acoustic lagging are available, several of which are specially made for isolating pipes. They often come in rolls suitable for this project and are quite simple to apply.

To install this, you'll need to measure the pipe you want to soundproof with a tape measure and cut the acoustic lagging appropriately. Then glue it to the pipe in various portions until the entire pipe is covered. The procedure is illustrated above when dealing with pipes in a wall cavity.

2. Spray Foam Insulation

Image Credits: building green

Spray foam insulation works well for low-moderate noises but is less effective than acoustic lagging at reducing noise. Additionally, it enhances insulation by maintaining a more constant temperature throughout the house.

To utilize it apply the spray evenly on the pipe's surface. The solution will thicken when it dries, dampening any pipe vibration-related noise.

3. Mass Loaded Vinyl

- Made in the USA - High Quality Mass Loaded Vinyl

- Perfect for Automobiles, Condos, Apartments, Studios and more

- No odor - Virgin material (no regrind or recycled material)

- 1 pound per sf (16 lbs total) - 1/8 of an inch thick - 26 STC

- Special sizing 4' x 4' (16 square feet) for smaller projects

The heavily loaded vinyl with mass is extremely dense, flexible, and quiet. It serves as a physical soundproof barrier by obstructing the passage of sound waves through it. Like acoustic lagging, you cut off parts of the material and attach them around the pipe you want to soundproof during installation.

4. Drywall or Gypsum Board Installation

Image Credits: quora

If your water supply pipes aren't accessible, you can add a layer of drywall or gypsum board with sound-absorbing material like foam panels. The installation of this layer reduces noise and muffles water transmission inside the pipes.

You will probably need professional assistance as this requires more specialized building abilities and construction understanding.

5. Rubber Spacers

Image Credits: made-in-china

Rubber spacers are excellent for reducing obtrusive noises brought on by loose PVC pipes. The rattling sounds are diminished when attached to the joints of connecting water pipes due to the rubber absorbing the vibration. In addition, rubber spacers help reduce pipe movement by ensuring that it is firmly fixed into place when a PVC pipe is in use.

6. Acoustic Pipe Wraps

Image Credits: allproof

Heat resistance and noise reduction are two characteristics of an acoustic pipe wrap. It provides excellent sound isolation even though it is not as effective as heavy-duty soundproofing materials.

Acoustic pipe wraps are an excellent option for anyone who wants to finish the job quickly since all that is required to complete the task is to wrap the material around each pipe tightly.

Image Credits: insulation victoria

Observe these steps to wrap noisy pipes:

- Make sure the pipe is free of dust and dirt by cleaning it.

- Measure the length of the pipe to calculate how much material you need.

- Trim the material as you wrap it around the pipe using a utility knife.

- Start from one end to the other.

- Pull back the edge of the backing to uncover 4 to 5 inches of peel-and-stick backing.

- Hold it at a small slant and push hard to ensure that the material sticks to the pipe properly.

- Peel the peel-and-stick backing and firmly push as you move down the pipe.

- Cut the material again and repeat the above steps until the pipe is completely covered if the material wrinkles.

- Your pipes will be less noisy and less likely to freeze in the winter if you wrap soundproof insulation around them.

Types of Pipe Noise

Image Credits: kay plumbing

1. Breakout noise

Breakout noise is a sound that enters a home or place of business through the building's walls. It frequently results from liquids such as water or other substances moving around the piping system concealed between walls and ceilings. Given that it cannot be easily silenced, it may be necessary to remove the drywall to address the issue.

2. Radiant Noise

Radiant noise develops due to the pipes' expansion during heating system operation. This occurs more frequently in older homes with less effective piping systems. These are frequently constructed of iron or copper, which corrode with time.

This could result in noise entering the house through the walls, necessitating the acoustic insulation of the pipe with either lagging or wrapping. PVC piping is used in many contemporary buildings because it is simple to handle and manipulate.

Tips on Soundproofing Pipes

Image Credits: soundproof panda

Take into account the following advice before beginning the soundproofing project:

1. Some pipe soundproofing materials can catch fire.

Be careful to select items or materials for soundproofing that have been heat-resistant.

2. Spray foam insulation is a quicker but messier substitute for acoustic lagging.

This is just a foam that you spray into the wall cavity. Only consider this approach when you are short on time and space because lagging is more useful.

3. Combine various pipes to save money.

For instance, only install quieter cast iron drain pipes in rooms that require low noise in place of noisy copper pipes.

Image Credits: soundbox acoustic

4. Enlist the assistance of friends or family members.

While it is possible to soundproof pipes on your own, it is more effective to have some help with measuring, cutting, and installing the materials.

5. Maximize the overall sound reduction.

To maximize the overall sound reduction, consider the soundproofing of the pipes and the walls. A smart approach to stop sound from passing through the walls is to install a thicker barrier.

6. Consider soundproofing pipes during the initial construction.

The best way to soundproof pipes is unquestionable as a comprehensive soundproofing operation. Soundproofing your drywall is smart, so why not finish the job while you're in there, taking it off to access the pipes?

Image Credits: soundproof central

7. Find the source of the noise.

Make sure the noise isn't coming from something dangerous before beginning your soundproofing endeavor. For example, a leak might bring it on, so conducting a thorough inspection of your piping system is worthwhile.

8. Think about your water pressure as well.

Another significant contributor to noisy pipes is high pressure, which can harm equipment. Install a pressure regulator if you find that your water pressure is excessive. These are reasonably priced and well worth the purchase.

9. Soundproofing and insulation.

Consider that many soundproofing concepts also apply to heat insulation; therefore, you may also wind up with a more effective heating system by soundproofing your pipes. Remember that this project could be rather large, so be sure you have everything you need before beginning.

The Advantages Of Soundproofing Pipes

Image Credits: aero foam

- Soundproof homes typically have better heat insulation, which can greatly save electrical bills and restore a calm environment.

- Soundproofing increases property value by improving the appeal of the living area to potential purchasers.

- Research shows that noise exposure regularly is associated with increased irritation, poorer sleep, and hearing impairment.

Featured Image Credits: insulationworldkenya