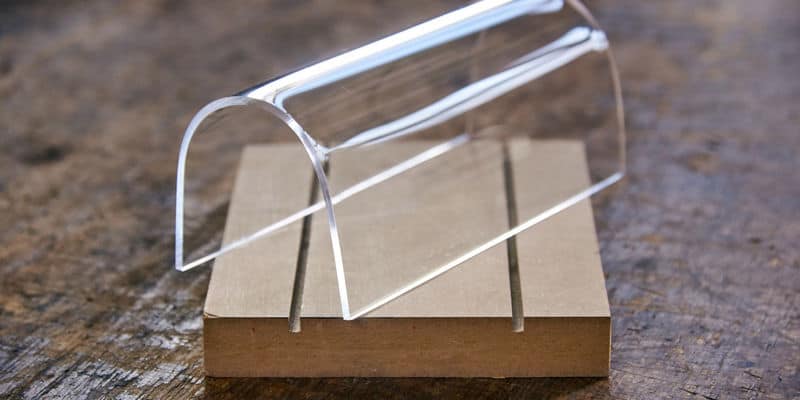

If you are wondering what plexiglass is, we have the answers! Plexiglass is a type of acrylic sheet that refers to different glass-like products manufactured under different names. In earlier years, manufacturers produced acrylic sheets under the name plexiglass. Currently, manufacturers create plexiglass acrylic products but term them under names such as acrylate, crylux, lucite, and perspex.

What Is Plexiglass Made Of?

Plexiglass, or sometimes what people call an acrylic sheet, is a transparent thermoplastic homopolymer product made in sheet form. It is a shatter-resistant and lightweight alternative to glass. Sometimes people refer to plexiglass as acrylic since it looks like actual glass and has a glass-like substance.

Acrylic is a synthetic polymer of methyl methacrylate, which is a plastic. It was developed in 1928 after different laboratory tests from different scientists simultaneously. The common name of acrylic sheeting is plexiglass, although the plexiglass with the capital P and S has been a registered trademark since 1933.

There exist other branded versions of plexiglass that include: lucite and crylux.

You can use plexiglass just like any other glass because it is sturdy and translucent. For example, let’s say you can add UV and other coatings. Plexiglass is an alternative to glass in most industries since it is versatile.

For instance, manufacturers may use plexiglass for light and instrument casings in cars or make appliances and eyewear lenses. When plexiglass is in sheet form, manufacturers may use it to make;

- Windows

- Lights

- Signs

- Bathroom fixtures

- Furniture

- Screens

- Reflective glass mirrors

Plexiglass has a ton of uses in different industrial fields. For instance, the medical and dental industry uses its purity and stability to make prosthetics and certain devices and instruments.

This traditional glass is also used in manufacturing submarines, airplanes, lighthouses and building some aesthetic parts of the sports arena since it is durable.

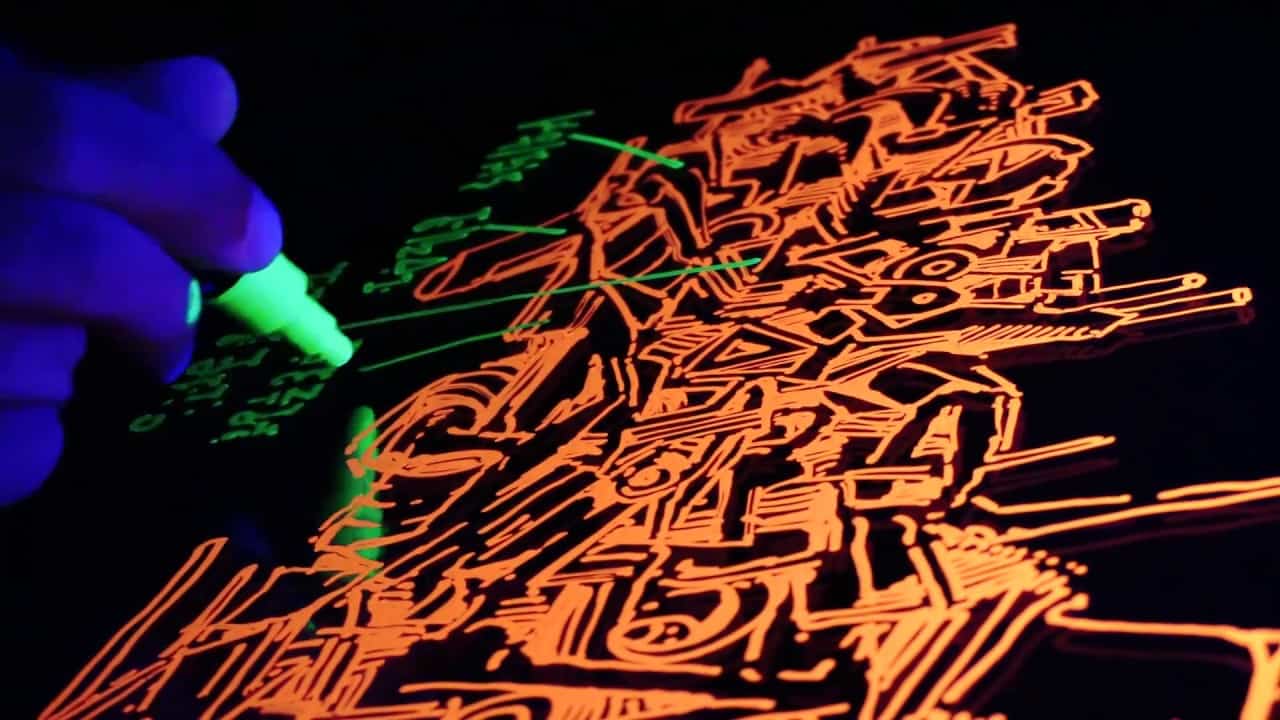

Artists also employ it in their paintings and sculptures to increase the aesthetic aspect of art. In addition, due to its durability and impact-resistant nature, it is used by manufacturers to create up to 33-foot aquariums that can bear maximum pressure.

The existence of plexiglass and its uses is fascinating but only useful for industrial purposes. If you are wondering how you can incorporate its uses in everyday life, we have outlined some common uses of plexiglass that may help you in your DIY projects.

What Are The Physical Properties Of Plexiglass?

1. Clear and Stronger Than Glass

You can use plexiglass as an alternative to regular glass window panels as they are clearer and stronger. In addition, they have a similar resemblance to glass. Furthermore, the clear plastic material makes it easy to clean and maintain since it does not attract dirt like other materials made of glass.

2. Easy To Cut

Plexiglass exists in a way you can easily cut it to the shape and size you desire. Glass is always hard to cut and may cause injuries during the process. Because of this property, you can use plexiglass to make stands, tabletops, shelf covers, and most of your home furnishings.

3. Shatter-resistant

As we had discussed earlier, plexiglass is strong and durable, making it the best fit for fixing your bathroom enclosures. In addition, handling plexiglass is quite easy as it does not crack easily, thus increasing its durability.

4. Impact Resistant

Impact resistance is a physical property that makes plexiglass a good fit for making submarine windows. The material is water resistant and can resist more impact compared to glass. It also offers a clearer view than glass, thus enabling most tourists to experience the best views of the ocean.

5. It has High Transparency

If you want to make big luxury windows or swimming pools, you should use clear plexiglass. The transparent material allows divers and coaches to monitor their swimming students easily.

6. It comes In Different Colors

Plexiglass is available in a variety of colors. Due to its multiple color themes, you can include it in signs, shelves, or gates that showcase directions.

Where To Buy Plexiglass

If you have already decided to use plexiglass instead of regular glass, you need to decide where to get it from. It would be best if you searched online for a reliable seller. A reliable seller should have a high-quality product with various selections. The plexiglass can come in different designs and shapes and should also be custom-made.

You should also consider the pricing and choose an online store with great after-sale services since they may they may install it for you for free. Again, the pricing should be cheap but for high-quality plexiglass.

If you are looking for plexiglass, custom-made or common ones, you can always refer to archute.com to get more ideas on what to choose. If your preference is either the transparent panel or clear plastic sheet, there is something for everyone!

Even if you are on a budget, there is always something to fit you; we have specialized customizable options from each category you can choose. You can go for a glass you want, and we will custom fit it to the style, color, texture, and design you want. Follow the ordering procedure on our website, and your plexiglass sheet will beautify your home in no time.

How Much Is A Sheet Of Plexiglass?

It is almost impossible to have an exact price of a sheet of plexiglass since most buyers have their preferences. Pricing may depend on various factors such as the size, thickness, and the number of sheets you want to purchase.

To be sure, you can use a direct quote from the online store you want to buy from. However, keep in mind that the more customized plexiglass you want, the more it will cost you.

How To Differentiate Plexiglass From Acrylic Glass

You might be wondering whether there is a difference between acrylic and plexiglass. The truth is both acrylic and plexiglass have more similarities than differences. Let us look at the notable differences between the two.

Typically, plexiglass and acrylic have more similarities; the only difference is in how they are manufactured. Acrylic sheets are manufactured using one of two processes; it could be through extrusion or cell casting. Extrude acrylic is the one manufactured through extrusion.

On the other hand, the cell cast process involves pouring unreacted acrylic between two glass panels to create a cell-like feature. After the reaction, the acrylic is cured. Then, the glass is separated from the acrylic, and the manufacturers inspect the acrylic.

This process is often time and labor-intensive, making cell cast acrylic slightly more expensive than extruded acrylic. However, you will be getting value for your money since cell cast acrylic is high quality and durable.

Plexiglass is normally manufactured using the cell cast process, explaining why they are always strong and durable. However, if you pay more for plexiglass, consider the cost and time of manufacturing that led to a high-quality product. Furthermore, the price may go higher if you customize the plexiglass to your need.

Why Choose Plexiglass Over Regular Glass Sheets

You may consider using plexiglass over acrylic plastic sheets for many reasons. However, acrylic sheets may not be the solution to all your building needs, which is why you can venture into using the plexiglass. We have outlined some reasons why we prefer plexiglass over acrylic sheets.

1. Plexiglass Is More Durable Compared To Plastic Glass

When you compare plexiglass to plastic glass, you will find that plexiglass is tougher than the regular glass we use daily. Plexiglass is made from sturdy acrylic sheets that are shatter-resistant. However, you should be careful while handling plexiglass as any rough treatment may lead to scratches and damage.

2. It Has Reduced Glare With Acrylic Glass

To achieve a clear view of your window panes, you should consider the plexiglass. The plexiglass offers a clear view regardless of the conditions your house or building may be facing. Using regular glass may experience reflections, especially when the light hits the glass from the wrong angles. This situation may lead to glare and dazzling.

3. Plexiglass Is Easier To Transport And Handle

Plexiglass weighs less than most similar-sized glass panels. As a result, it makes it easier to transport, handle or install it in your new premise. Also, since it is lightweight, there are fewer chances that the glass may get damaged during transportation or installation.

4. It Is Easy To Clean

If you have cleaned glass before, you are aware of the hassles of the whole process. First, you must do a neat job by ensuring no residues remain. The traditional plexiglass sheet is often easy to clean, requiring standard household cleaning products.

On the other hand, acrylic plastic sheets are hard to clean since they require special solvents to prevent them from getting disclosed, clouded, or even cracking.

5. Plexiglass Sheets Are Less Expensive

In most cases, the regular glass sheets cost less than other plastic glass. However, acrylic glass sheets may be expensive when they have extra features like UV protection or when manufacturers add glare-resistant coatings.

But, if you add the initial cost of most plexiglass panels, you will find that they last longer and have a reduced risk of breakage compared to acrylic sheeting, making them less expensive.

What Are The Uses Of Plexiglass Sheets?

As discussed earlier, plexiglass is lighter than clear plastic sheets, less expensive, and easy to install. Most builders prefer it since it is less prone to breakage and damage. Due to its characteristics, Plexiglass is used in place of glass. You can use plexiglass to make:

1. Durable Windows

As we discussed earlier, plexiglass sheets are more durable than acrylic sheeting, making them suitable for making durable windows. In addition, there is not much difference in physical visibility as plexiglass is also as clear acrylic sheets.

It is best to use plexiglass to achieve durable windows as the see-through effect is the same as the fragile glass ones. The durable material used to make plexiglass makes it easier to maintain since it does not collect too much dirt. You can easily wipe through the glass as it does not leave any residues behind.

Plexiglass is resistant to breakage and thus less likely to crack or stain in harsh weather conditions. The above properties make plexiglass the logical choice to see in skylights.

2. Bath Glass

You can use plexiglass to create beautiful and safe bathroom enclosures. Plexiglass is more slip resistant and shatter-proof compared to regular glass. You can test a piece of plexiglass by shattering it, and it will not break.

Using plexiglass in bathroom enclosures reduces the risk of getting bathroom injuries such as sliding or falling. The same properties make it suitable for fences and furnishings such as stools, shelves, and tabletops.

3. Greenhouses

If you are into farming, you can explore using plexiglass to make greenhouses. It is made of sturdy material and can let light sip through.

Since it is stable, it guards against the breakage of panes. Also, since it does not stain or crack easily, it is easy to maintain as it will ensure a steady supply of sunlight without collecting dirt on top. Furthermore, it comes at a relatively low cost, making it ideal for making greenhouses.

4. Solar Panels

Using solar panels is basically trying to say you are going the natural way but with minimal effort. If you are switching to using solar panels as a means of electricity, the best material to use in the solar panel is plexiglass.

It resists harsh weather conditions and is way better than tempered glass. In addition, it is shatter resistant and allows 90% of light to sip through the panels. What more benefit would you want from a glass than this? So when you are shopping for solar panels, keep in mind that you need plexiglass.

5. Making Food Display Protectors

You can use plexiglass in food industries by customizing it as a food protector. The plexiglass offers a clear display of the food being sold and guards the food against dust or flies. In most cases, supermarkets display vegetables or fresh meat for customers to purchase.